Page 478 - Book Hosokawa Nanoparticle Technology Handbook

P. 478

APPLICATIONS 7 FORMATION OF THICK ELECTRONIC CERAMIC FILMS

[48] H. Li, J.H. Song, J.S. Park and K. Han: Int. J. Pharm., [51] J. Du, S. Zhang, R. Sun, L.F. Zhang, C.D. Xiong and

258, 11–19 (2003). Y.X. Peng: J. Biomed. Mater. Res., 72B, 299–304 (2005).

[49] M.S. Mesiha, M.B. Sidhom and B. Fasipe: Int. [52] M.G. Fuentes, D. Torres and M.J. Alonso: Int. J. Pharm.,

J. Pharm., 288, 289–293 (2005). 296, 122–132 (2005).

[50] A.C. Foss, T. Goto, M. Morishita and N.A. Peppas: [53] K.H. Song, S.J. Chung and C.K. Shim: J. Control.

Eur. J. Pharm. Biopharm., 57, 163–169 (2004). Release, 106, 298–308 (2005).

APPLICATION 7

7 FORMATION OF THICK ELECTRONIC CERAMIC FILMS WITH BONDING

TECHNIQUE OF CRYSTALLINE FINE PARTICLES AND THEIR APPLICATIONS

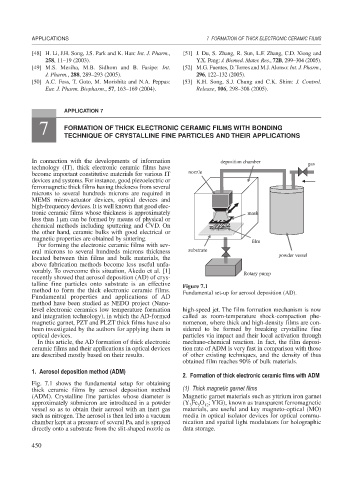

In connection with the developments of information deposition chamber gas

technology (IT), thick electronic ceramic films have

become important constitutive materials for various IT nozzle

devices and systems. For instance, good piezoelectric or

ferromagnetic thick films having thickness from several

microns to several hundreds microns are required in

MEMS micro-actuator devices, optical devices and

high-frequency devices. It is well known that good elec-

tronic ceramic films whose thickness is approximately mask

less than 1 m can be formed by means of physical or

chemical methods including sputtering and CVD. On

the other hand, ceramic bulks with good electrical or

magnetic properties are obtained by sintering. film

For forming the electronic ceramic films with sev-

eral microns to several hundreds microns thickness substrate powder vessel

located between thin films and bulk materials, the

above fabrication methods become less useful unfa-

vorably. To overcome this situation, Akedo et al. [1] Rotary pump

recently showed that aerosol deposition (AD) of crys-

talline fine particles onto substrate is an effective Figure 7.1

method to form the thick electronic ceramic films. Fundamental set-up for aerosol deposition (AD).

Fundamental properties and applications of AD

method have been studied as NEDO project (Nano-

level electronic ceramics low temperature formation high-speed jet. The film formation mechanism is now

and integration technology), in which the AD-formed called as room-temperature shock-compaction phe-

magnetic garnet, PZT and PLZT thick films have also nomenon, where thick and high-density films are con-

been investigated by the authors for applying them in sidered to be formed by breaking crystalline fine

optical devices. particles via impact and their local activation through

In this article, the AD formation of thick electronic mechano-chemical reaction. In fact, the film deposi-

ceramic films and their applications in optical devices tion rate of ADM is very fast in comparison with those

are described mostly based on their results. of other existing techniques, and the density of thus

obtained film reaches 90% of bulk materials.

1. Aerosol deposition method (ADM)

2. Formation of thick electronic ceramic films with ADM

Fig. 7.1 shows the fundamental setup for obtaining

thick ceramic films by aerosol deposition method (1) Thick magnetic garnet films

(ADM). Crystalline fine particles whose diameter is Magnetic garnet materials such as yttrium iron garnet

approximately submicron are introduced in a powder (Y Fe O ; YIG), known as transparent ferromagnetic

5

3

12

vessel so as to obtain their aerosol with an inert gas materials, are useful and key magneto-optical (MO)

such as nitrogen. The aerosol is then led into a vacuum media in optical isolator devices for optical commu-

chamber kept at a pressure of several Pa, and is sprayed nication and spatial light modulators for holographic

directly onto a substrate from the slit-shaped nozzle as data storage.

450