Page 479 - Book Hosokawa Nanoparticle Technology Handbook

P. 479

7 FORMATION OF THICK ELECTRONIC CERAMIC FILMS APPLICATIONS

0.4

0.2 0

Faraday rotation F (deg/Hm) -0.4

-0.2

-0.6

1 μm -0.8 before anneal

-1

700 °C 60 min annealed

-1.4

Figure 7.2 -1.2

Cross-sectional image of the AD-formed thick Bi:YIG film. -1.6

400 500 600 700 800 900

Wavelength (nm)

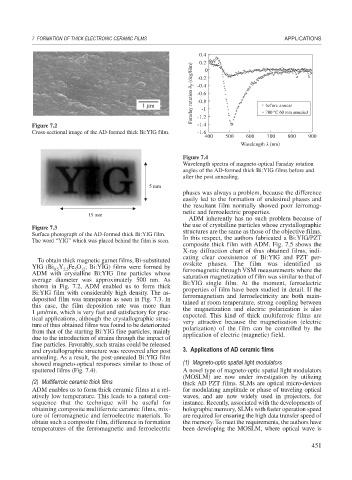

Figure 7.4

Wavelength spectra of magneto-optical Faraday rotation

angles of the AD-formed thick Bi:YIG films before and

after the post annealing.

5 mm

phases was always a problem, because the difference

easily led to the formation of undesired phases and

the resultant film normally showed poor ferromag-

netic and ferroelectric properties.

15 mm

ADM inherently has no such problem because of

the use of crystalline particles whose crystallographic

Figure 7.3

Surface photograph of the AD-formed thick Bi:YIG film. structures are the same as those of the objective films.

The word “YIG” which was placed behind the film is seen. In this respect, the authors fabricated a Bi:YIG/PZT

composite thick film with ADM. Fig. 7.5 shows the

X-ray diffraction chart of thus obtained films, indi-

cating clear coexistence of Bi:YIG and PZT per-

To obtain thick magnetic garnet films, Bi-substituted

YIG (Bi Y Fe O ; Bi:YIG) films were formed by ovskite phases. The film was identified as

ferromagnetic through VSM measurements where the

12

0.5

2.5

5

ADM with crystalline Bi:YIG fine particles whose saturation magnetization of film was similar to that of

average diameter was approximately 500 nm. As Bi:YIG single film. At the moment, ferroelectric

shown in Fig. 7.2, ADM enabled us to form thick properties of film have been studied in detail. If the

Bi:YIG film with considerably high density. The as- ferromagnetism and ferroelectricity are both main-

deposited film was transparent as seen in Fig. 7.3. In tained at room temperature, strong coupling between

this case, the film deposition rate was more than the magnetization and electric polarization is also

1 m/min, which is very fast and satisfactory for prac- expected. This kind of thick multiferroic films are

tical applications, although the crystallographic struc- very attractive because the magnetization (electric

ture of thus obtained films was found to be deteriorated polarization) of the film can be controlled by the

from that of the starting Bi:YIG fine particles, mainly application of electric (magnetic) field.

due to the introduction of strains through the impact of

fine particles. Favorably, such strains could be released

and crystallographic structure was recovered after post 3. Applications of AD ceramic films

annealing. As a result, the post-annealed Bi:YIG film

showed magneto-optical responses similar to those of (1) Magneto-optic spatial light modulators

sputtered films (Fig. 7.4). A novel type of magneto-optic spatial light modulators

(MOSLM) are now under investigation by utilizing

(2) Multiferroic ceramic thick films thick AD PZT films. SLMs are optical micro-devices

ADM enables us to form thick ceramic films at a rel- for modulating amplitude or phase of traveling optical

atively low temperature. This leads to a natural con- waves, and are now widely used in projectors, for

sequence that the technique will be useful for instance. Recently, associated with the developments of

obtaining composite multiferroic ceramic films, mix- holographic memory, SLMs with faster operation speed

ture of ferromagnetic and ferroelectric materials. To are required for ensuring the high data transfer speed of

obtain such a composite film, difference in formation the memory. To meet the requirements, the authors have

temperatures of the ferromagnetic and ferroelectric been developing the MOSLM, where optical wave is

451