Page 480 - Book Hosokawa Nanoparticle Technology Handbook

P. 480

APPLICATIONS 7 FORMATION OF THICK ELECTRONIC CERAMIC FILMS

G

YIG

YI

PZT

PZT

n

eal

ed

Annealed

A

n

Intensity (A.U.) Intensity (A.U.) A s-fo r med

°

C

at 500

at 500 °C

As-formed

Powder

Po wd er

20 25 30 35 40 45

20

45

25

30

40

35

2 2 (deg)

g)

(de

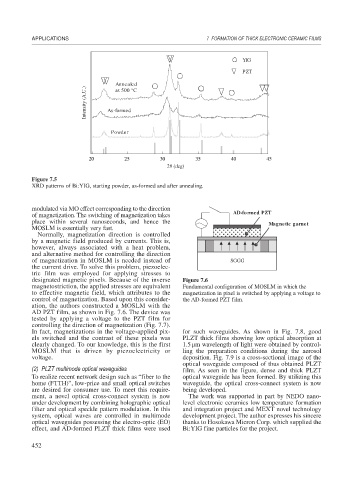

Figure 7.5

XRD patterns of Bi:YIG, starting powder, as-formed and after annealing.

modulated via MO effect corresponding to the direction

of magnetization. The switching of magnetization takes AD-formed PZT

place within several nanoseconds, and hence the Magnetic garnet

MOSLM is essentially very fast.

Normally, magnetization direction is controlled

by a magnetic field produced by currents. This is,

however, always associated with a heat problem,

and alternative method for controlling the direction

of magnetization in MOSLM is needed instead of SGGG

the current drive. To solve this problem, piezoelec-

tric film was employed for applying stresses to

designated magnetic pixels. Because of the inverse Figure 7.6

magnetostriction, the applied stresses are equivalent Fundamental configuration of MOSLM in which the

to effective magnetic field, which attributes to the magnetization in pixel is switched by applying a voltage to

control of magnetization. Based upon this consider- the AD-formed PZT film.

ation, the authors constructed a MOSLM with the

AD PZT film, as shown in Fig. 7.6. The device was

tested by applying a voltage to the PZT film for

controlling the direction of magnetization (Fig. 7.7).

In fact, magnetizations in the voltage-applied pix- for such waveguides. As shown in Fig. 7.8, good

els switched and the contrast of these pixels was PLZT thick films showing low optical absorption at

clearly changed. To our knowledge, this is the first 1.5 m wavelength of light were obtained by control-

MOSLM that is driven by piezoelectricity or ling the preparation conditions during the aerosol

voltage. deposition. Fig. 7.9 is a cross-sectional image of the

optical waveguide composed of thus obtained PLZT

(2) PLZT multimode optical waveguides film. As seen in the figure, dense and thick PLZT

To realize recent network design such as “fiber to the optical waveguide has been formed. By utilizing this

home (FTTH)”, low-price and small optical switches waveguide, the optical cross-connect system is now

are desired for consumer use. To meet this require- being developed.

ment, a novel optical cross-connect system is now The work was supported in part by NEDO nano-

under development by combining holographic optical level electronic ceramics low temperature formation

filter and optical speckle pattern modulation. In this and integration project and MEXT novel technology

system, optical waves are controlled in multimode development project. The author expresses his sincere

optical waveguides possessing the electro-optic (EO) thanks to Hosokawa Micron Corp. which supplied the

effect, and AD-formed PLZT thick films were used Bi:YIG fine particles for the project.

452