Page 577 - Book Hosokawa Nanoparticle Technology Handbook

P. 577

30 NOZZLE-FREE INKJET TECHNOLOGY APPLICATIONS

X-Y stage

Vessel and

Ultra sonic vibrator

Inkjet part

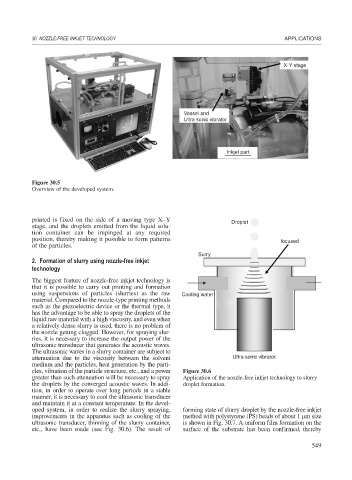

Figure 30.5

Overview of the developed system.

printed is fixed on the side of a moving type X–Y Droplet

stage, and the droplets emitted from the liquid solu-

tion container can be impinged at any required

position, thereby making it possible to form patterns focused

of the particles.

Surry

2. Formation of slurry using nozzle-free inkjet

technology

The biggest feature of nozzle-free inkjet technology is

that it is possible to carry out printing and formation

using suspensions of particles (slurries) as the raw Cooling water

material. Compared to the nozzle-type printing methods

such as the piezoelectric device or the thermal type, it

has the advantage to be able to spray the droplets of the

liquid raw material with a high viscosity, and even when

a relatively dense slurry is used, there is no problem of

the nozzle getting clogged. However, for spraying slur-

ries, it is necessary to increase the output power of the

ultrasonic transducer that generates the acoustic waves.

The ultrasonic waves in a slurry container are subject to

attenuation due to the viscosity between the solvent Ultra sonic vibrator

medium and the particles, heat generation by the parti-

cles, vibration of the particle structure, etc., and a power Figure 30.6

greater than such attenuation will be necessary to spray Application of the nozzle-free inkjet technology to slurry

the droplets by the converged acoustic waves. In addi- droplet formation.

tion, in order to operate over long periods in a stable

manner, it is necessary to cool the ultrasonic transducer

and maintain it at a constant temperature. In the devel-

oped system, in order to realize the slurry spraying, forming state of slurry droplet by the nozzle-free inkjet

improvements in the apparatus such as cooling of the method with polystyrene (PS) beads of about 1 m size

ultrasonic transducer, thinning of the slurry container, is shown in Fig. 30.7. A uniform film formation on the

etc., have been made (see Fig. 30.6). The result of surface of the substrate has been confirmed, thereby

549