Page 72 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 72

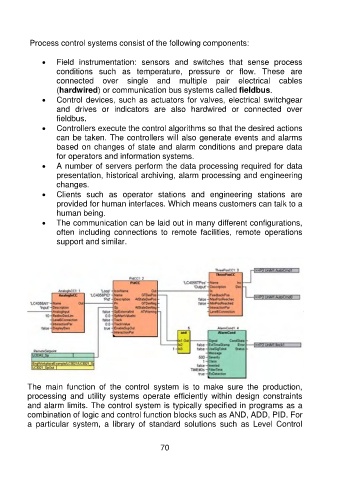

Process control systems consist of the following components:

• Field instrumentation: sensors and switches that sense process

conditions such as temperature, pressure or flow. These are

connected over single and multiple pair electrical cables

(hardwired) or communication bus systems called fieldbus.

• Control devices, such as actuators for valves, electrical switchgear

and drives or indicators are also hardwired or connected over

fieldbus.

• Controllers execute the control algorithms so that the desired actions

can be taken. The controllers will also generate events and alarms

based on changes of state and alarm conditions and prepare data

for operators and information systems.

• A number of servers perform the data processing required for data

presentation, historical archiving, alarm processing and engineering

changes.

• Clients such as operator stations and engineering stations are

provided for human interfaces. Which means customers can talk to a

human being.

• The communication can be laid out in many different configurations,

often including connections to remote facilities, remote operations

support and similar.

The main function of the control system is to make sure the production,

processing and utility systems operate efficiently within design constraints

and alarm limits. The control system is typically specified in programs as a

combination of logic and control function blocks such as AND, ADD, PID. For

a particular system, a library of standard solutions such as Level Control

70