Page 74 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 74

• Optimization of various processes to increase capacity or reduce

energy costs.

• Pipeline management modeling, leak detection and pig tracking.

• Support for remote operations, in which facility data is available to

company specialists located at a central support center.

• Support for remote operations where the entire facility is unmanned

or without local operators full or part time, and is operated from a

remote location.

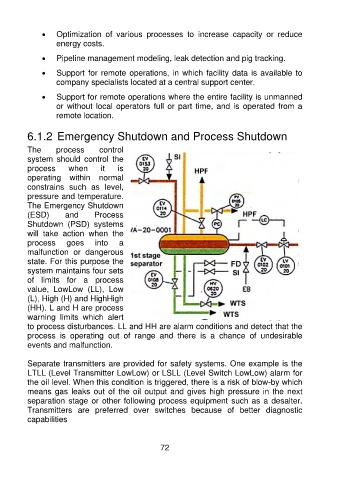

6.1.2 Emergency Shutdown and Process Shutdown

The process control

system should control the

process when it is

operating within normal

constrains such as level,

pressure and temperature.

The Emergency Shutdown

(ESD) and Process

Shutdown (PSD) systems

will take action when the

process goes into a

malfunction or dangerous

state. For this purpose the

system maintains four sets

of limits for a process

value, LowLow (LL), Low

(L), High (H) and HighHigh

(HH). L and H are process

warning limits which alert

to process disturbances. LL and HH are alarm conditions and detect that the

process is operating out of range and there is a chance of undesirable

events and malfunction.

Separate transmitters are provided for safety systems. One example is the

LTLL (Level Transmitter LowLow) or LSLL (Level Switch LowLow) alarm for

the oil level. When this condition is triggered, there is a risk of blow-by which

means gas leaks out of the oil output and gives high pressure in the next

separation stage or other following process equipment such as a desalter.

Transmitters are preferred over switches because of better diagnostic

capabilities

72