Page 313 - Organic Electronics in Sensors and Biotechnology

P. 313

290 Chapter Seven

(b) the realization of a photochemically altered surface layer for

increasing the refractive index. Straight single-mode waveguides and

multimode interference couplers for the NIR spectrum fabricated by

this approach have already been demonstrated. 95

Waveguide-Coupled Organic Semiconductor Lasers

The above-mentioned fabrication techniques enable the fabrication of

an integrated waveguide-coupled organic semiconductor laser. A

first success was the coupling of amplified spontaneous emission

generated in an organic semiconductor layer into an underlying deep

96

UV patterned waveguide. Recently, an integrated laser with strongly

25

(20×) enhanced coupling efficiency has been demonstrated. This

waveguide-coupled laser was fabricated with three main process

steps.

• Hot embossing of first-order DFB laser resonators

• Waveguide definition through deep UV exposure of PMMA

• Deposition of the active laser material Alq :DCM

3

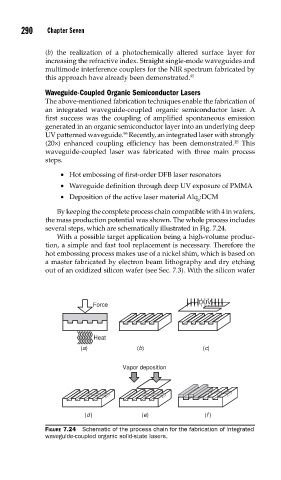

By keeping the complete process chain compatible with 4 in wafers,

the mass production potential was shown. The whole process includes

several steps, which are schematically illustrated in Fig. 7.24.

With a possible target application being a high-volume produc-

tion, a simple and fast tool replacement is necessary. Therefore the

hot embossing process makes use of a nickel shim, which is based on

a master fabricated by electron beam lithography and dry etching

out of an oxidized silicon wafer (see Sec. 7.3). With the silicon wafer

Force DUV

Heat

(a) (b) (c)

Vapor deposition

(d ) (e) (f )

FIGURE 7.24 Schematic of the process chain for the fabrication of integrated

waveguide-coupled organic solid-state lasers.