Page 392 - Organic Electronics in Sensors and Biotechnology

P. 392

Electrophoretically Deposited Polymers for Organic Electronics 369

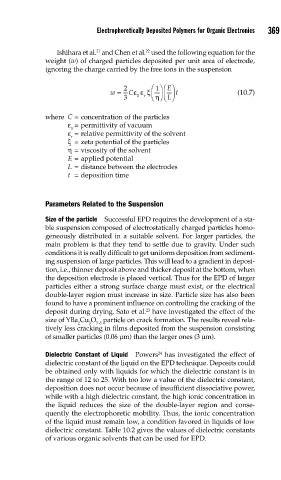

Ishihara et al. and Chen et al. used the following equation for the

22

21

weight (w) of charged particles deposited per unit area of electrode,

ignoring the charge carried by the free ions in the suspension

1

2 ⎛ ⎞ ⎛ E⎞

w = Cεε ξ t (10.7)

r ⎜ ⎟ ⎜ ⎟

η

3 0 ⎝ ⎠ ⎝ L⎠

where C = concentration of the particles

ε = permittivity of vacuum

0

ε = relative permittivity of the solvent

r

ξ = zeta potential of the particles

η = viscosity of the solvent

E = applied potential

L = distance between the electrodes

t = deposition time

Parameters Related to the Suspension

Size of the particle Successful EPD requires the development of a sta-

ble suspension composed of electrostatically charged particles homo-

geneously distributed in a suitable solvent. For larger particles, the

main problem is that they tend to settle due to gravity. Under such

conditions it is really difficult to get uniform deposition from sediment-

ing suspension of large particles. This will lead to a gradient in deposi-

tion, i.e., thinner deposit above and thicker deposit at the bottom, when

the deposition electrode is placed vertical. Thus for the EPD of larger

particles either a strong surface charge must exist, or the electrical

double-layer region must increase in size. Particle size has also been

found to have a prominent influence on controlling the cracking of the

23

deposit during drying. Sato et al. have investigated the effect of the

size of YBa Cu O particle on crack formation. The results reveal rela-

2 3 7-δ

tively less cracking in films deposited from the suspension consisting

of smaller particles (0.06 μm) than the larger ones (3 μm).

24

Dielectric Constant of Liquid Powers has investigated the effect of

dielectric constant of the liquid on the EPD technique. Deposits could

be obtained only with liquids for which the dielectric constant is in

the range of 12 to 25. With too low a value of the dielectric constant,

deposition does not occur because of insufficient dissociative power,

while with a high dielectric constant, the high ionic concentration in

the liquid reduces the size of the double-layer region and conse-

quently the electrophoretic mobility. Thus, the ionic concentration

of the liquid must remain low, a condition favored in liquids of low

dielectric constant. Table 10.2 gives the values of dielectric constants

of various organic solvents that can be used for EPD.