Page 342 - Orlicky's Material Requirements Planning

P. 342

CHAPTER 19 Repetitive Manufacturing Application 321

Production Sales Inventory

June 100,000 50,000 75,000

120,000 50,000 82,000

July 120,000 60,000 88,000

120,000 60,000 94,000

August 120,000 100,000 96,000

150,000 100,000 101,000

September 150,000 100,000 106,000

200,000 200,000 106,000

October 200,000 200,000 106,000

200,000 400,000 86,000

November 300,000 400,000 76,000

300,000 400,000 66,000

December 200,000 400,000 46,000

200,000 400,000 26,000

January 200,000 200,000 26,000

200,000 200,000 26,000

February 200,000 100,000 36,000

200,000 100,000 46,000

March 200,000 100,000 56,000

200,000 80,000 68,000

April 100,000 80,000 70,000

100,000 50,000 75,000

May 100,000 50,000 80,000

100,000 50,000 85,000

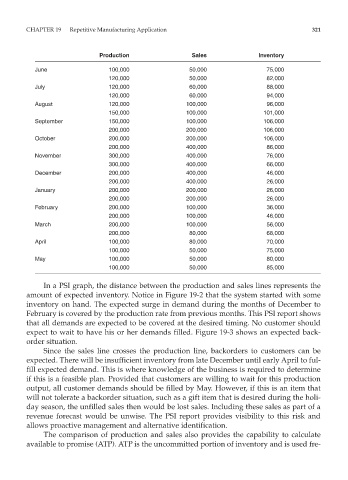

In a PSI graph, the distance between the production and sales lines represents the

amount of expected inventory. Notice in Figure 19-2 that the system started with some

inventory on hand. The expected surge in demand during the months of December to

February is covered by the production rate from previous months. This PSI report shows

that all demands are expected to be covered at the desired timing. No customer should

expect to wait to have his or her demands filled. Figure 19-3 shows an expected back -

order situation.

Since the sales line crosses the production line, backorders to customers can be

expected. There will be insufficient inventory from late December until early April to ful-

fill expected demand. This is where knowledge of the business is required to determine

if this is a feasible plan. Provided that customers are willing to wait for this production

output, all customer demands should be filled by May. However, if this is an item that

will not tolerate a backorder situation, such as a gift item that is desired during the holi-

day season, the unfilled sales then would be lost sales. Including these sales as part of a

revenue forecast would be unwise. The PSI report provides visibility to this risk and

allows proactive management and alternative identification.

The comparison of production and sales also provides the capability to calculate

available to promise (ATP). ATP is the uncommitted portion of inventory and is used fre-