Page 200 - Photodetection and Measurement - Maximizing Performance in Optical Systems

P. 200

Contamination and Industrial Systems

Contamination and Industrial Systems 193

system does help, and transmission reduction to 10 percent of that of the clean

state can usually be encompassed. Nevertheless, the reduction in light will cer-

tainly reduce the S/N and increase errors due to the numerical division

processes involved in compensation. The technique is used both for liquid

absorption measurements using four transmission determinations, as well as

for turbidity measurements with determination of two transmitted and two

scattered intensities. Other combinations and geometrical arrangements are

possible. The electronic division limitations are not fundamental, and could in

principle be lifted through higher resolution ADCs, brighter, self-adjusting

sources, etc. We should really be asking what are the remaining fundamental

limits of the technique which preclude perfect compensation?

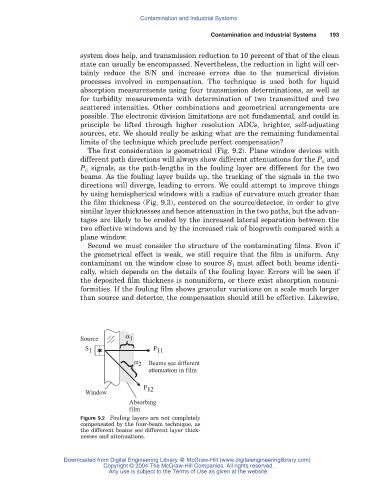

The first consideration is geometrical (Fig. 9.2). Plane window devices with

different path directions will always show different attenuations for the P ii and

P ij signals, as the path-lengths in the fouling layer are different for the two

beams. As the fouling layer builds up, the tracking of the signals in the two

directions will diverge, leading to errors. We could attempt to improve things

by using hemispherical windows with a radius of curvature much greater than

the film thickness (Fig. 9.3), centered on the source/detector, in order to give

similar layer thicknesses and hence attenuation in the two paths, but the advan-

tages are likely to be eroded by the increased lateral separation between the

two effective windows and by the increased risk of biogrowth compared with a

plane window.

Second we must consider the structure of the contaminating films. Even if

the geometrical effect is weak, we still require that the film is uniform. Any

contaminant on the window close to source S 1 must affect both beams identi-

cally, which depends on the details of the fouling layer. Errors will be seen if

the deposited film thickness is nonuniform, or there exist absorption nonuni-

formities. If the fouling film shows granular variations on a scale much larger

than source and detector, the compensation should still be effective. Likewise,

Source 1 } a

S 1 P 11

} a 2 Beams see different

attenuation in film

P 12

Window

Absorbing

film

Figure 9.2 Fouling layers are not completely

compensated by the four-beam technique, as

the different beams see different layer thick-

nesses and attenuations.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.