Page 201 - Photodetection and Measurement - Maximizing Performance in Optical Systems

P. 201

Contamination and Industrial Systems

194 Chapter Nine

Absorbing

biofilm

a

Source } 1 P

S 1 11

} a 2 Two beams see

similar film thicknesses

Domed

window P 12

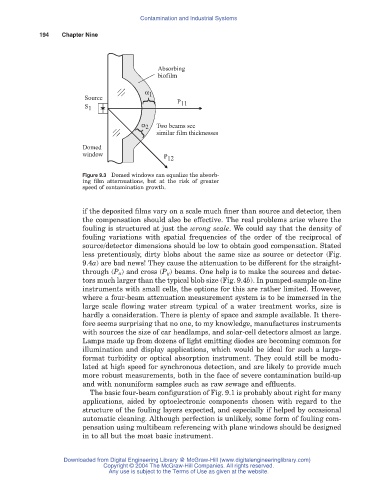

Figure 9.3 Domed windows can equalize the absorb-

ing film atternuations, but at the risk of greater

speed of contamination growth.

if the deposited films vary on a scale much finer than source and detector, then

the compensation should also be effective. The real problems arise where the

fouling is structured at just the wrong scale. We could say that the density of

fouling variations with spatial frequencies of the order of the reciprocal of

source/detector dimensions should be low to obtain good compensation. Stated

less pretentiously, dirty blobs about the same size as source or detector (Fig.

9.4a) are bad news! They cause the attenuation to be different for the straight-

through (P ii) and cross (P ij) beams. One help is to make the sources and detec-

tors much larger than the typical blob size (Fig. 9.4b). In pumped-sample on-line

instruments with small cells, the options for this are rather limited. However,

where a four-beam attenuation measurement system is to be immersed in the

large scale flowing water stream typical of a water treatment works, size is

hardly a consideration. There is plenty of space and sample available. It there-

fore seems surprising that no one, to my knowledge, manufactures instruments

with sources the size of car headlamps, and solar-cell detectors almost as large.

Lamps made up from dozens of light emitting diodes are becoming common for

illumination and display applications, which would be ideal for such a large-

format turbidity or optical absorption instrument. They could still be modu-

lated at high speed for synchronous detection, and are likely to provide much

more robust measurements, both in the face of severe contamination build-up

and with nonuniform samples such as raw sewage and effluents.

The basic four-beam configuration of Fig. 9.1 is probably about right for many

applications, aided by optoelectronic components chosen with regard to the

structure of the fouling layers expected, and especially if helped by occasional

automatic cleaning. Although perfection is unlikely, some form of fouling com-

pensation using multibeam referencing with plane windows should be designed

in to all but the most basic instrument.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.