Page 213 - Pipeline Pigging Technology

P. 213

Pipeline Ftyging Technology

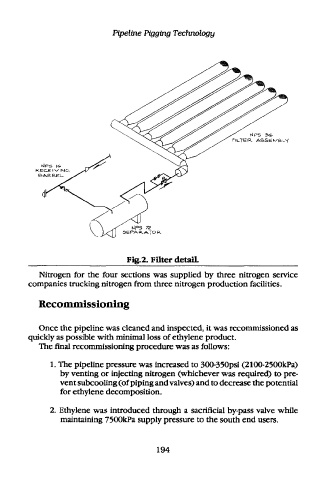

Fig.2. Filter detail

Nitrogen for the four sections was supplied by three nitrogen service

companies trucking nitrogen from three nitrogen production facilities.

Recommissioning

Once the pipeline was cleaned and inspected, it was recommissioned as

quickly as possible with minimal loss of ethylene product.

The final recommissioning procedure was as follows:

1. The pipeline pressure was increased to 300-350psi (2100-2500kPa)

by venting or injecting nitrogen (whichever was required) to pre-

vent subcooling (of piping and valves) and to decrease the potential

for ethylene decomposition.

2. Ethylene was introduced through a sacrificial by-pass valve while

maintaining 7500kPa supply pressure to the south end users.

194