Page 214 - Pipeline Pigging Technology

P. 214

Ethylene pipeline cleaning

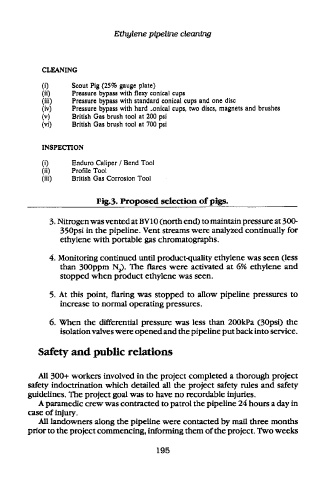

CLEANING

(i) Scout Pig (25% gauge plate)

(ii) Pressure bypass with flexy conical cups

(iii) Pressure bypass with standard conical cups and one disc

(iv) Pressure bypass with hard ^onical cups, two discs, magnets and brushes

(v) British Gas brush tool at 200 psi

(vi) British Gas brush tool at 700 psi

INSPECTION

(i) Enduro Caliper / Bend Tool

(ii) Profile Tool

(iii) British Gas Corrosion Tool

Fig.3. Proposed selection of pigs.

3. Nitrogen was vented at BV10 (north end) to maintain pressure at 300-

350psi in the pipeline. Vent streams were analyzed continually for

ethylene with portable gas chromatographs.

4. Monitoring continued until product-quality ethylene was seen (less

than 300ppm N^. The flares were activated at 6% ethylene and

stopped when product ethylene was seen.

5. At this point, flaring was stopped to allow pipeline pressures to

increase to normal operating pressures.

6. When the differential pressure was less than 200kPa (30psi) the

isolation valves were opened and the pipeline put back into service.

Safety and public relations

All 300+ workers involved in the project completed a thorough project

safety indoctrination which detailed all the project safety rules and safety

guidelines. The project goal was to have no recordable injuries.

A paramedic crew was contracted to patrol the pipeline 24 hours a day in

case of injury.

All landowners along the pipeline were contacted by mail three months

prior to the project commencing, informing them of the project. Two weeks

195