Page 215 - Pipeline Pigging Technology

P. 215

Pipeline Pigging Technology

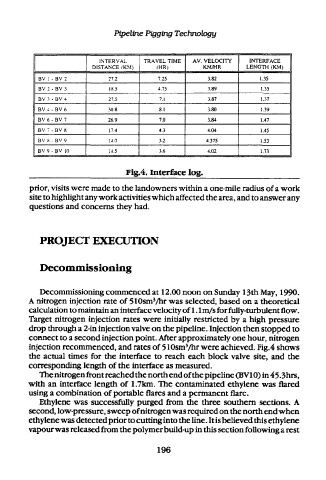

Fig.4. Interface log.

prior, visits were made to the landowners within a one-mile radius of a work

site to highlight any work activities which affected the area, and to answer any

questions and concerns they had.

PROJECT EXECUTION

Decommissioning

Decommissioning commenced at 12.00 noon on Sunday 13th May, 1990.

3

A nitrogen injection rate of 510sm /hr was selected, based on a theoretical

calculation to maintain an interface velocity of 1.1 m/s for fully-turbulent flow.

Target nitrogen injection rates were initially restricted by a high pressure

drop through a 2-in injection valve on the pipeline. Injection then stopped to

connect to a second injection point. After approximately one hour, nitrogen

3

injection recommenced, and rates of 510sm /hr were achieved. Fig.4 shows

the actual times for the interface to reach each block valve site, and the

corresponding length of the interface as measured.

The nitrogen front reached the north end of the pipeline (BV10) in 453hrs,

with an interface length of 1.7km. The contaminated ethylene was flared

using a combination of portable flares and a permanent flare.

Ethylene was successfully purged from the three southern sections. A

second, low-pressure, sweep of nitrogen was required on the north end when

ethylene was detected prior to cutting into the line. It is believed this ethylene

vapour was released from the polymer build-up in this section following a rest

196