Page 8 - Pipeline Rules of Thumb Handbook

P. 8

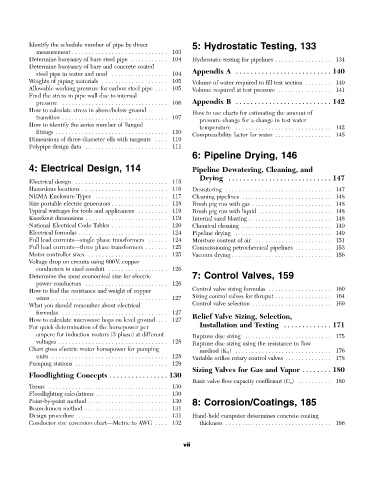

Identify the schedule number of pipe by direct 5: Hydrostatic Testing, 133

measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Determine buoyancy of bare steel pipe . . . . . . . . . . . 104 Hydrostatic testing for pipelines . . . . . . . . . . . . . . . . . 134

Determine buoyancy of bare and concrete coated Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . 140

steel pipe in water and mud . . . . . . . . . . . . . . . . . 104

Weights of piping materials . . . . . . . . . . . . . . . . . . . . 105 Volume of water required to fill test section . . . . . . . . 140

Allowable working pressure for carbon steel pipe . . . . 105 Volume required at test pressure . . . . . . . . . . . . . . . . 141

Find the stress in pipe wall due to internal

pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . 142

How to calculate stress in above/below ground

How to use charts for estimating the amount of

transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

pressure change for a change in test water

How to identify the series number of flanged

temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Compressibility factor for water . . . . . . . . . . . . . . . . . 145

Dimensions of three-diameter ells with tangents . . . . 110

Polypipe design data . . . . . . . . . . . . . . . . . . . . . . . . . 111

6: Pipeline Drying, 146

4: Electrical Design, 114 Pipeline Dewatering, Cleaning, and

Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Electrical design . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . 116 Dewatering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

NEMA Enclosure Types . . . . . . . . . . . . . . . . . . . . . . 117 Cleaning pipelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Size portable electric generators . . . . . . . . . . . . . . . . . 118 Brush pig run with gas . . . . . . . . . . . . . . . . . . . . . . . . 148

Typical wattages for tools and applicances . . . . . . . . . 119 Brush pig run with liquid . . . . . . . . . . . . . . . . . . . . . . 148

Knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 119 Internal sand blasting . . . . . . . . . . . . . . . . . . . . . . . . . 148

National Electrical Code Tables . . . . . . . . . . . . . . . . . 120 Chemical cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Electrical formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 Pipeline drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Full load currents—single phase transformers . . . . . . 124 Moisture content of air . . . . . . . . . . . . . . . . . . . . . . . 151

Full load currents—three phase transformers . . . . . . . 125 Commissioning petrochemical pipelines . . . . . . . . . . . 153

Motor controller sizes . . . . . . . . . . . . . . . . . . . . . . . . 125 Vacuum drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Voltage drop on circuits using 600V. copper

conductors in steel conduit . . . . . . . . . . . . . . . . . . 126

Determine the most economical size for electric 7: Control Valves, 159

power conductors . . . . . . . . . . . . . . . . . . . . . . . . . 126

How to find the resistance and weight of copper Control valve sizing formulas . . . . . . . . . . . . . . . . . . . 160

wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 Sizing control valves for thruput . . . . . . . . . . . . . . . . . 164

What you should remember about electrical Control valve selection . . . . . . . . . . . . . . . . . . . . . . . . 169

formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 Relief Valve Sizing, Selection,

How to calculate microwave hops on level ground . . . 127

For quick determination of the horsepower per Installation and Testing . . . . . . . . . . . . . 171

ampere for induction motors (3 phase) at different Rupture disc sizing . . . . . . . . . . . . . . . . . . . . . . . . . . 175

voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 Rupture disc sizing using the resistance to flow

Chart gives electric motor horsepower for pumping method (K R ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 Variable orifice rotary control valves . . . . . . . . . . . . . . 178

Pumping stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Sizing Valves for Gas and Vapor . . . . . . . . 180

Floodlighting Concepts . . . . . . . . . . . . . . . . 130

Basic valve flow-capacity coefficient (C v ) . . . . . . . . . . 180

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Floodlighting calculations . . . . . . . . . . . . . . . . . . . . . . 130

Point-by-point method . . . . . . . . . . . . . . . . . . . . . . . . 130 8: Corrosion/Coatings, 185

Beam-lumen method . . . . . . . . . . . . . . . . . . . . . . . . . 131

Design procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 131 Hand-held computer determines concrete coating

Conductor size coversion chart—Metric to AWG . . . . 132 thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

vii