Page 138 - Power Electronics Handbook

P. 138

Overcurrent protection 131

End terminal

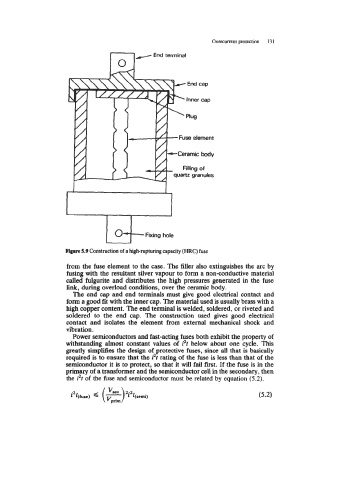

Figure 5.9 Construction of a high-rupturing capacity (HRC) fuse

from the fuse element to the case. The filler also extinguishes the arc by

fusing with the resultant silver vapour to form a non-conductive material

called fulgurite and distributes the high pressures generated in the fuse

link, during overload conditions, over the ceramic body.

The end cap and end terminals must give good electrical contact and

form a good fit with the inner cap. The material used is usually brass with a

high copper content. The end terminal is welded, soldered, or riveted and

soldered to the end cap. The construction used gives good electrical

contact and isolates the element from external mechanical shock and

vibration.

Power semiconductors and fast-acting fuses both exhibit the property of

withstanding almost constant values of i2f below about one cycle. This

greatly simplifies the design of protective fuses, since all that is basically

required is to ensure that the i2t rating of the fuse is less than that of the

semiconductor it is to protect, so that it will fail first. If the fuse is in the

primary of a transformer and the semiconductor cell in the secondary, then

the i2t of the fuse and semiconductor must be related by equation (5.2).