Page 79 - Practical Design Ships and Floating Structures

P. 79

54

sub-module for each constraint type. To date, only a limited number of modules are available (in

general 1 or 2 for each constraint type). It is up to the user to complete, adapt and add new modules

according to his specific requirements (type of structure, codes and regulations to be followed,

technical and scientific level, available hardware, etc.). The objective is to enable the user himself to

build the tool he needs.

Figures 1 and 2 show the basic configuration of the LBR-5 software with the 3 fundamental modules

(COST, CONSTRAINT and OPTI) and the "DATABASES" in which the user can do his "shopping",

i.e. chbose the relevant constraints and cost data. After selecting the geometrical and structural

constraints and cost assessment tools in the databanks.

3 DESCRIPTION OF THE 3 BASIC MODULES: OPTI, CONSTRAINT AND COST

The problems to be solved can be summarised as follows:

xi i = 1, N, the N design variables,

F(Xi) the objective function to minimize,

m Cj(Xi) I CM, j = 1 ,M the M structural and geometrical constraints,

XiminSXi 5 Xima upper and lower bounds of the Xi design variables:

technological bounds (also called side Constraints).

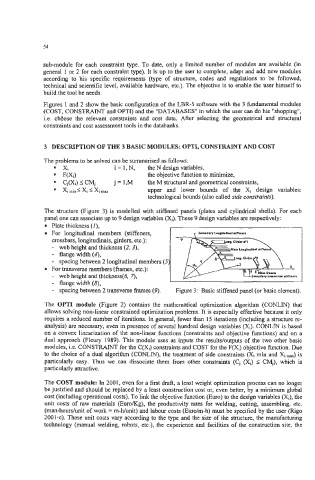

The structure (Figure 3) is modelled with stiffened panels (plates and cylindrical shells). For each

panel one can associate up to 9 design variables (Xi). These 9 design variables are respectively:

Plate thickness (I),

For longitudinal members (stiffeners,

crossbars, longitudinals, girders, etc.):

- web height and thickness (2, 3),

- flangewidth(4,

- spacing between 2 longitudinal members (

For transverse members (fnunes, etc.):

- web height and thickness(6, 7),

- flange width (8),

- spacing between 2 transverse frames (9). Figure 3: Basic stiffened panel (or basic element).

The OPTI module (Figure 2) contains the mathematical optimization algorithm (CONLM) that

allows solving non-linear constrained optimization problems. It is especially effective because it only

requires a reduced number of iterations. In general, fewer than 15 iterations (including a structure re-

analysis) are necessary, even in presence of several hundred design variables (Xi). CONLN is based

on a convex linearization of the non-linear functions (constraints and objective functions) and on a

dual approach (Fleury 1989). This module uses as inputs the resultdoutputs of the two other basic

modules, i.e. CONSTRAINT for the C(Xi) constraints and COST for the F(Xi) objective function. Due

to the choice of a dual algorithm (CONLIN), the treatment of side constraints (Xi min and Xi ,=) is

particularly easy. Thus we can dissociate them from other constraints (C, (Xi) I CM,), which is

particularly attractive.

The COST module: In 2001, even for a first draft, a least weight optimization process can no longer

be justified and should be replaced by a least construction cost or, even better, by a minimum global

cost (including operational costs). To link the objective function (Euro) to the design variables (Xi), the

unit costs of raw materials (EuroKg), the productivity rates for welding, cutting, assembling, etc.

(man-hourslunit of work = m-Wunit) and labour costs (Euro/m-h) must be specified by the user (Rig0

2001-c). These unit costs vary according to the type and the size of the structure, the manufacturing

technology (manual welding, robots, etc.), the experience and facilities of the construction site, the