Page 82 - Practical Design Ships and Floating Structures

P. 82

57

0 ,, = min [ a (mode i), i = a, b, c and d. the 4 considered failure modes]

Level 3: Mode a: Global buckling.

Mode b: P,,,, of interframe panels (beam-column or orthotropic models)

- plate induced failure (buckling),

- stiffener induced failure (buckling or yielding).

Mode c: Instability of stiffeners (local buckling, tripping, etc.).

Mode d: Yielding.

To avoid constraints related to the ”a” mode, one generally imposes a minimal rigidity for the

transverse frames so that an interframe panel collapse (mode b) always appears before global buckling

(mode a).

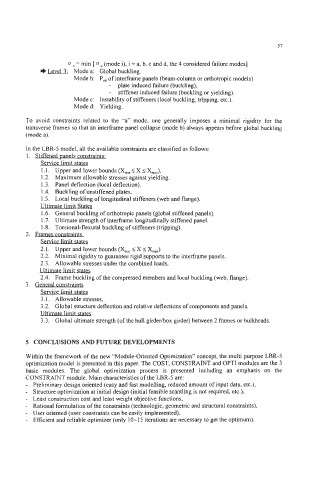

In the LBR-5 model, all the available constraints are classified as follows:

1. Stiffened panels constd

.

ervice 11- ..

X

1.1. Upper and lower bounds (x,“ I X,,,J,

I

I .2. Maximum allowable stresses against yielding.

1.3. Panel deflection (local deflection).

1.4. Buckling of unstiffened plates,

1.5. Local buckling of longitudinal stiffeners (web and flange).

..

e limit Stm

1.6. General buckling of orthotropic panels (global stiffened panels).

1.7. Ultimate strength of interframe longitudinally stiffened panel.

1.8. Torsional-flexural buckling of stiffeners (tripping).

2. Erames constrad

2. I. Upper and lower bounds (X,,, 5 X I x,,,)

2.2. Minimal rigidity to guarantee rigid supports to the interframe panels.

2.3. Allowable stresses under the combined loads,

..

ate limit

2.4. Frame buckling of the compressed members and local buckling (web, flange).

J. WeJal co nstraw

Service limit states

3. I. Allowable stresses,

3.2. Global structure deflection and relative deflections of components and panels.

m e limit states

3.3. Global ultimate strength (of the hull girderhx girder) between 2 frames or bulkheads.

5 CONCLUSIONS AND FUTURE DEVELOPMENTS

Within the framework of the new “Module-Oriented Optimization” concept. the multi purpose LBR-5

optimization model is presented in this paper. The COST, CONSTRAINT and OPT1 modules are the 3

basic modules. The global optimization process is presented including an emphasis on the

CONSTRAINT module. Main characteristics of the LBR-5 are:

- Preliminary design oriented (easy and fast modelling, reduced amount of input data, etc.),

- Structure optimization at initial design (initial feasible scantling is not required, etc.),

- Least construction cost and least weight objective functions,

- Rational formulation of the constraints (technologic, geometric and structural constraints),

- User oriented (user constraints can be easily implemented),

- Efficient and reliable optimizer (only 10-15 iterations are necessary to get the optimum).