Page 86 - Practical Design Ships and Floating Structures

P. 86

61

2.3 Optimization of Local Hull Lines (Level 2)

Reynolds Average Navier-Stokes (RANS) equations with 2-turbulence model and linear free surface

boundary condition, together with the differential numerical approach (Wang and Wan, 1991; Wang

and Wang, 1994; Wang and Wang, 1995; and Wang and Wang, 1996) are applied to simulate flow

around ship hull in time domain. The objective functions are the viscous resistance coefficient and the

wave-making resistance coefficient, with the local hull lines being the optimization object.

2.4 Optimization of Appendage Lines (Level 3)

Partly-parabolic type of Navier-Stokes equations with 2-turbulence model by use of differential

numerical approach with the pressure marching or the finite-volume method (Wang and Cai, 1998; Li,

Lin and Wang, 1997; Li, Lin and Wang, 1998) is used to simulate flow considering the interaction

between hull and propeller. The objective functions are the viscous resistance (coefficient) and the

wake fraction and the optimized objects are local hull lines, appendage lines and propeller set.

2.5 Optimization of Finalizing Hull Lines (Level 4)

Model test is employed to confirm the optimization result. In fact the information both for the

optimized model and for the modification of tested model can be obtained from the computations

based on Level 2 and 3.

At present the relative accuracy of predicting resistance performance by using CFD code can be

ensured, that means it could be used to make comparison with different models. But the final

prediction of hull resistance should be determined by use of model test. Up to now the CFD code can

predict the resistance performance of ship hull with model size (Re = 106-7) and thus the model test

can be camed out under the same scale of computational model. The prediction of resistance

performance for a ship with full scale (generally Re = lo8-’) should consider the scale effects.

Ship designers hope that the resistance performance could be directly predicted by a suitable CFD

code, and hence the requirement of model test could be minimized. However this objective may only

be partly achieved for some of series ships and for ships that have support from big relative database.

For new ship form developing the model test is necessary and all of CFD’s results must be validated by

model tests.

3 APPLICATION

DSMT tanker model as an example of optimization process is provided as follows. The optimization of

Level 2 has been made after Level 0 and 1.

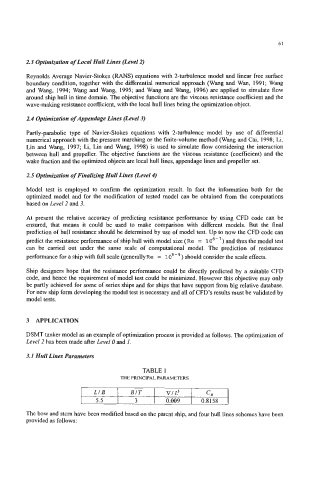

3.1 Hull Lines Parameters

TABLE 1

THE PRINCIPAL PARAMETERS

5.5 3 I 0.009 I 0.8158

The bow and stem have been modified based on the parent ship, and four hull lines schemes have been

provided as follows: