Page 151 - Pressure Vessel Design Manual

P. 151

Design of Vessel Supports 129

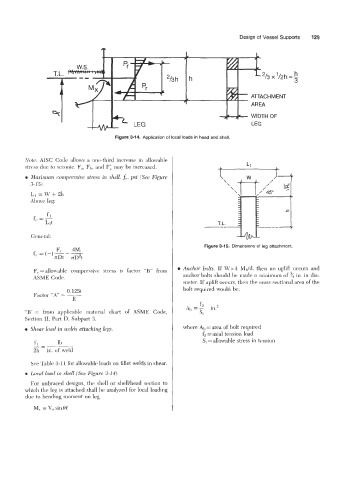

Figure 3-14. Application of local loads in head and shell.

Yote AISC Code allows a one-third increase in allowable

stress due to seismic. F,, Fi,, and Fi may be increased.

~Mazirni~rn conipressive stress in shell, fc, psi (See Figure

3-15).

Li =W+2h

Above leg:

fl

f --

- Llt

Figure 3-15. Dimensions of leg attachment.

f - (-)--- F, 4Mt

c-

TDt rD2t

Anchor bolts. If W > 4 Mdd, then no uplift occurs and

F,. = allow7ahle compressive stress is Lactor “B” from

ASME Code. anchor bolts should be made a minimum of ”/, in. in dia-

meter. If uplift occurs, then the cross-sectional area of the

bolt required would be:

fz

A,, = s; in.2

“R”= from applicable material chart of ASME Code,

Section 11, Part D, Subpart 3.

Shear load in weld.$ attaching legs. where Ab = area of bolt required

fi = axial tension load

_- 1b St = allowable stress in tension

fl

2h - in. of weld

See Table 3-11 for allowable loads on fillet welds in shear.

L0c:d load in shell (See Figure 3-14).

For unbraced designs, the shell or shellhead section to

which the leg is attached shall be analyzed for local loading

due to bending moment on leg.

M, = \’” sin 0C