Page 75 - Pressure Vessel Design Manual

P. 75

56 Pressure Vessel Design Manual

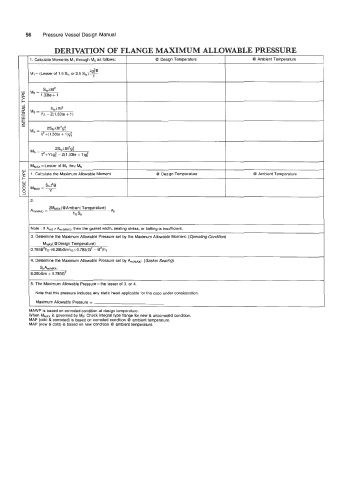

DERIVATION OF FLANGE MAXIMUM ALLOWABLE PRESSURE

1. Calculate Moments M, through M5 as follows: I @ Design Temperature I @ Ambient Temperature

MI = (Lesser of 1.5 Sf, or 2.5 Sfa) &I: B

f

~

Sf,hBt2

M2 =-

I .33te + 1

SfohBt2

M3 =

YA - Z(1.33te + 1)

2StoABt2g:

Mq =

f?+(l.33te + 1)g:

MMAX = Lesser of MI thru M5

1. Calculate the Maximum Allowable Moment @ Design Temperature @ Ambient Temperature

I I

2.

~MMAX( @Ambient Temperature)

&(MAX) = - Ab

hGSa

Note : If Am2>Am(MA~), then the gasket width, seating stress, or bolting is insufficient.

3. Determine the Maximum Allowable Pressure set by the Maximum Allowable Moment: (Operating Condition)

M~m(@Design Temperature)

0.785B2hD+6.28bGmh~+0.785(G2 - B')h,

4. Determine the Maximum Allowable Pressure set by Am(~~x): (Gasket Seating)

SbAm(MAX)

6.28bGm + 0.785G2

5. The Maximum Allowable Pressure = the lesser of 3. or 4.

Note that this pressure includes any static head applicable for the case under consideration.

Maximum Allowable Pressure =

MAWP is based on corroded condition at design temperature.

When MMAX is governed by Mz: Check integral type flange for new & uncorroded condition.

MAP (cold & corroded) is based on corroded condition @ ambient temperature.

MAP (new & cold) is based on new condition @ ambient temperature.