Page 79 - Pressure Vessel Design Manual

P. 79

60 Pressure Vessel Design Manual

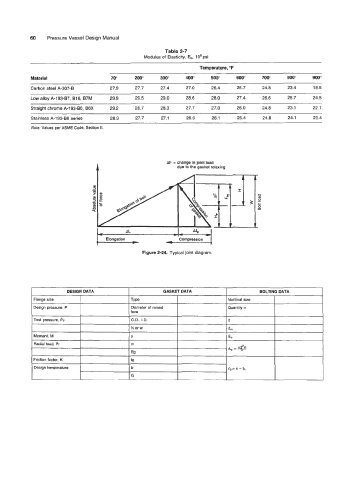

Table 2-7

Modulus of Elasticity, Eb, 1 O6 psi

Temperature, 'F

Material 70" 200" 300" 400" 500" 600" 700" 800" 900"

Carbon steel A-307-B 27.9 27.7 27.4 27.0 26.4 25.7 24.8 23.4 18.5

Low alloy A-1 93-87, B16, B7M 29.9 29.5 29.0 28.6 28.0 27.4 26.6 25.7 24.5

Straight chrome A-193-B6, B6X 29.2 28.7 28.3 27.7 27.0 26.0 24.8 23.1 22.1

Stainless A-1 93-88 series 28.3 27.7 27.1 26.6 26.1 25.4 24.8 24.1 23.4

Note: Values per ASME Code, Section II.

1 AF = change in joint load

due to the gasket relaxing

m

--

AL -,

Elongation - Compression

*-

Figure 2-24. Typical joint diagram.

DESIGN DATA GASKET DATA BOLTING DATA

Flange size I TY Pe Nominal size

Design pressure, P Diameter of raised Quantity n

face

~

O.D., 1.D. d

N or w I d,

Moment, M I

Radial load, Pr I

~

Friction factor, K

Design temperature