Page 83 - Pressure Vessel Design Manual

P. 83

64 Pressure Vessel Design Manual

1 < (1.1 -?)a Case 4 (Figure 2-29)

or

I 1

for length 2 6 and taper is 4:l minimum.

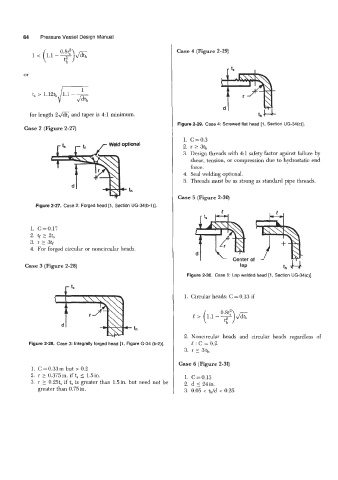

Figure 2-29. Case 4: Screwed flat head [l , Section UG-34(c)].

Case 2 (Figure 2-27)

1. C=0.3

2. r 2 3th

3. Design threads with 4:l safety factor against failure by

shear, tension, or compression due to hydrostatic end

force.

4. Seal welding optional.

5. Threads must be as strong as standard pipe threads.

Case 5 (Figure 2-30)

Figure 2-27. Case 2: Forged head [l , Section UG-34(b-1)].

1. C=0.17

2. tf 1 2t,

3. r 2 3tf

4. For forged circular or noncircular heads.

Case 3 (Figure 2-28)

Figure 2-30. Case 5: Lap welded head [l , Section UG-34(c)].

1. Circular heads: C = 0.13 if

e > (1.1 -?)A

fh

2. Noncircular heads and circular heads regardless of

Figure 2-28. Case 3: Integrally forged head [l , Figure 6-34 (b-2)]. e : c = 0.2.

3. r 13th

Case 6 (Figure 2-31)

1. C = 0.33 m but > 0.2

2. r 2 0.375in. if t, 5 1.5in. 1. C=0.13

3. r 3 0.25ts if t, is greater than Sin. but need not be 2. d 5 24in.

greater than 0.75in. 3. 0.05 < tlJd < 0.25