Page 84 - Pressure Vessel Design Manual

P. 84

General Design 65

r

fh

Bevel optional

Figure 2-33. Case 8: Welded flat heads (Full penetration welds re-

Figure 2-31. Case 6: Integrally forged head [l, Section UG-34(d)]. quired) [l , Section UG-34(g)].

4. 4, L ts

5. r 2 0.25t1,

6. Head integral with shell by upsetting, forging, or spin- 3. See Note 3 in Case 7

ning.

7. Circular heads only. Case 9 (Figure 2-34)

Case 7 (Figure 2-32)

-1 Type 1

Projection optional '

Backing

Figure 2-32. Case 7: Welded flat heads [l , Section UG-34(e)(f)]. strip may

be used

1. Circular heads: C = 0.33 m but 2 0.2. If m < 1, then

shell cannot be tapered within 2& from inside of

head.

2. Noncircular heads: C = 0.33

3. Liquid penetrant (L.P.) or magnetic particle test (M.T.)

end of shell and O.D. of head if t, or th is greater than

1/2 in. thick (before and after welding).

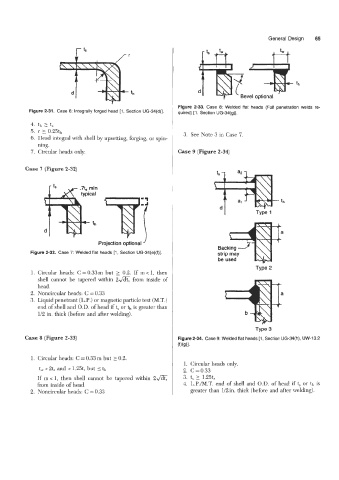

Case 8 (Figure 2-33) Figure 2-34. Case 9: Welded flat heads [l , Section UG-34(h), UW-13.2

(f)(g)l.

1. Circular heads: C = 0.33 m but 20.2.

1. Circular heads only.

tl,

t, > 2t, and > 1.25tS but I 2. C=O.33

If in < 1, then shell cannot be tapered within 2& 3. t, 2 1.25tr

from inside of head. 4. L.P./M.T. end of shell and O.D. of head if t, or th is

2. Noncircular heads: C = 0.33 greater than 1/2 in. thick (before and after welding).