Page 85 - Pressure Vessel Design Manual

P. 85

66 Pressure Vessel Design Manual

5. Type 1: al+az>2t,

0.5a2 c al < 2a2 Retaining

Type 2: a > 2t, ring

Type 3: a+b>2t, fh

b = 0 is permissible

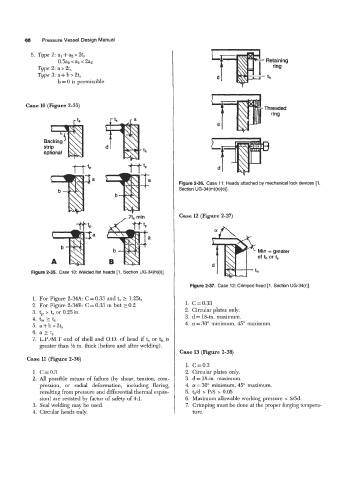

Case 10 (Figure 2-35) Threaded

ring

Backing L

strip

optional

d

Figure 2-36. Case 11: Heads attached by mechanical lock devices [l,

Section UG-34(m)(n)(o)].

Case 12 (Figure 2-37)

a

Min = greater

of th or 1,

d @th

Figure 2-35. Case 10: Welded flat heads [l, Section UG-34(h)(i)].

Figure 2-37. Case 12: Crimped head [l, Section UG-34(r)].

1. For Figure 2-34A C = 0.33 and t, 2 1.25tr

2. For Figure 2-34B: C = 0.33 m but 2 0.2 1. C=0.33

3. tp > t, or 0.25in. 2. Circular plates only.

4. tw 2 ts 3. d= &in. maximum.

5. a-tb>2tS 4. a = 30" minimum, 45" maximum.

6. a 2 t,

7. L.P./M.T end of shell and O.D. of head if t, or th is

greater than M in. thick (before and after welding).

Case 13 (Figure 2-38)

Case 11 (Figure 2-36)

1. C=0.3

1. C=0.3 2. Circular plates only.

2. All possible means of failure (by shear, tension, com- 3. d = 18-in. maximum.

pression, or radial deformation, including flaring, 4. 01 = 30" minimum, 45" maximum.

resulting from pressure and differential thermal expan- 5. t,/d > P/S > 0.05

sion) are resisted by factor of safety of 4:l. 6. Maximum allowable working pressure e S/5d.

3. Sed welding may be used. 7. Crimping must be done at the proper forging tempera-

4. Circular heads only. ture.