Page 81 - Pressure Vessel Design Manual

P. 81

62 Pressure Vessel Design Manual

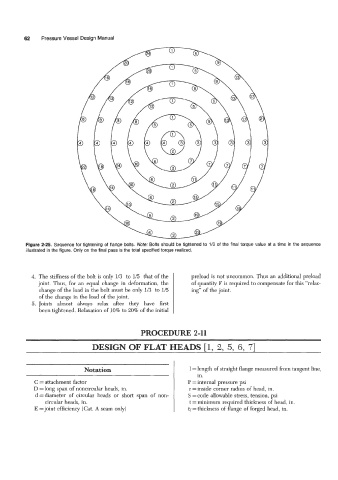

Figure 2-25. Sequence for tightening of flange bolts. Note: Bolts should be tightened to 1/3 of the final torque value at a time in the sequence

illustrated in the figure. Only on the final pass is the total specified torque realized.

4. The stiffness of the bolt is only 1/3 to 1/5 that of the preload is not uncommon. Thus an additional preload

joint. Thus, for an equal change in deformation, the of quantity F is required to compensate for this “relax-

change of the load in the bolt must be only 1/3 to 1/5 ing” of the joint.

of the change in the load of the joint.

5. Joints almost always relax after they have first

been tightened. Relaxation of 10% to 20% of the initial

PROCEDURE 2-11

DESIGN OF FLAT HEADS 11, 2. 5. 6. 71

Notation 1 =length of straight flange measured from tangent line,

in.

~

C = attachment factor P = internal pressure psi

D = long span of noncircular heads, in. r =inside comer radius of head, in.

d=diameter of circular heads or short span of non- S =code allowable stress, tension, psi

circular heads, in. t = minimum required thickness of head, in.

E =joint efficiency (Cat. A seam only) tf= thickness of flange of forged head, in.