Page 325 - Pressure Swing Adsorption

P. 325

! (

PRESSURE SWING ADSORPTION MEMBRANE PROCESSES 303

302

Roffinate at their most economic for production of a pure raffinate product. Although

Raffinote

Product B•(A) Product B+(A) Permeate a cascade of several stages can oroduce a permeate product' of high purity,

Product A•(B}

,--1 I such processes are seldom econom1cal except when the value of the products

1

1s unusually high.

i

!

8.5 Comparison of PSA and Membrane Processes

( for Air Separation

ReJect

A•IBI

8.5.1 Nitrogen Production

The purity-recovery profile for a PSA nitrogen process operating between

Feed, A• 8

Feed A•B 5.0 and 1.0 atm on the cycle of Figure 3.17 with the Bcrgbau-Forschung

( ri l (bl (cl carbon molecular sieve adsorbent is compared with the corresponding mem-

brane process m Figure 8.7. Bnef details of the operating conditions which

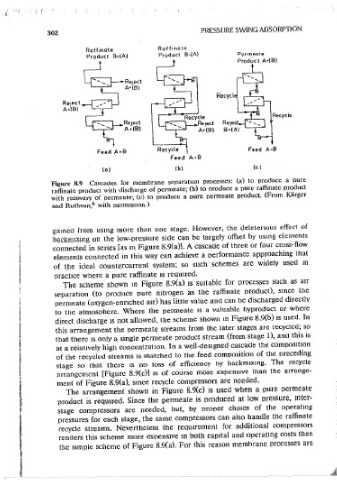

Figure 8.9 Cascades for membrane separation processes: (a) to or~duce a pure are typical of such processes, are given in Table 6:1. The profile for a real

ramnate product wilh discharge of permeate; (b) to produce a pure rathnate or~_duct membrane system will lie between the theoretical Curves calculated for the

with recoverv of permeate~· (c) to produce a pure permeate product. (From Karger

ideal countercurrent and cross-flow cases. For a 'Permeability ratio of 5,

and Ruthven, with permission.)

6

which 1s typical of the preseni generation of membrane processes, the

performance of the membrane system, in the moderate- to highwpurlty

g;lmcct from uSmg more than one stage. However, the deietenous ~ffect. of regime, ts similar to that of the PSA process. The profiles for the membrane

backmtxing on the low-pressure side can be largely offset by using elements and PSA processes are, however, of different form so that ·the PSA system

connected in series fas in Figure 8.9(a)l. A cascade of three or four cross-flow gains a margtnal advantage m the high-punty region while the membrane

elements connected in this way can achieve a performance approaching that system becomes clearly advantageous when product purity reau1rements are

of the ideal countercurrent system; so such schemes are widely usect m less severe. In both processes the power reou1red to compress the feed a1r 1s

practice where a pure raffinate 1s reqmred. the main component of the operatmg cost; so cotnparing recOverv-punty

The scheme shown m Figure 8.9(a) 1s smtable for processes such as a1r profiles at the same pressure ratio orovides a direct comoanson of the

separation (td produce pure nitrogen as the raffinate product), smce the operating cost comoonent. The overall process economics are, however,

permeate (oxygenwenriched atr) has little value and can be discharged directly modified by differences in cao1tai cost and operational life: so the simple

to the atmosphere. Where the permeate 1s a valuable byproduct or where companson based on recovery-punty profiles orovides only a rot,1gh guide.

direct discharge 1s not allowed, the scheme shown m Figure 8.9(b) 1s usect. In The carbon molecular sieve process has been operational for about IO

this arrangement the permeat~ streams from the later stages are recycled.; s_o years, and the process has therefore been fatrJy well opt1m1zed. The present

that there 1s only a single peftneate product stream (from stage 1), and this 1s generation of the CMS adsorbents offers a diffus1v1ty ratio of about 100 but

at a relatively high concentration. In a well-designed cascade the comoos1t1on the recoveiy-punty profile is relatively insensitive to a further increase in this

of the recycled streams is matched to the feed composition of the preceding ratio. In contrast, the present generation of membranes have ·oermeabilitv

stage so that there 1s no loss of efficiency by backm1xmg. The recycle ratios of 5-6, and, although higher selectivity membranes are availahle, the

arrangement [Figure 8.9(c)l 1s of course more expensive than the arrange- permeability ts generally too low (sec· Figure 8.4). However, It 1s clear that a

ment of Figure 8.9(a), since recycle compressors are needed. relativeiy modest increase in membrane sclcct1v1ty would give the membrane

The arrangement shown in Figure 8.9(c) 1s used when a pure permeate process a cJear economic advantage over the comoeting PSA process for

product is reamred. Since the permeate is produced at low pressure, mter, nitrogen production.

~tage compre~sors are needed, but, by proper ch01ce of the operating Results of a more detaiied economic evaluation taking account of both

pressures for each stage, the same compressors can aiso handle the raffinate camtal and operating costs are shown m Figure 8.]0. At sufficiently large

recycle streams. Nevertheless the requirement for addjtional compressors scales of operation the cryogemc process 1s the best choice. PSA and

I renders this scheme more expensive m both capital and operating costs than combined with a DEOXO unit (see Section 6.3) both these processes can

membrane processes are preferred for smallerwscale processes, ancl when

tile simple scheme of Figure 8.9(a). For this reason membrane processes are

I