Page 328 - Pressure Swing Adsorption

P. 328

,Ii

304 PRESSURE SWING ADSORPTION MEMBRANE PROCESSES 30S

ornxo _::.J:_£RYOGENIC +---- Mole Percent Oxygen

100 i::i:=i:-±=-=i=:l==:1±=::t CRYO NIC 100~-------~-- LIQUID 02 ·-AIR PLANT

CYLINDERS

.-----J--1=::::;--t-,

UN 90 ,. OR

99.5 PIPELINE

\ 80 VSA I

...

>- 99 ' /; 70 · PSA

I

ii:

::, 60 ·

0.

z 98.5 ' 60 I

w \ I I

"'

0

a: 1 40 · MEMBRANE

... 98

z PSA OR -i 30 I I

MEMBRANE I

20 ..i. . ..LIJJIJIL._LJ.Ll.JtilL......J.....LL.lUlll~.L.1...Ull.lU._____L...l..U.J.JIIL_.J,__J.J_J.lUU_.J.....Ll.llill

0.01 0.1 10 100 1,000 10,000 100,000

l Flow - Pure Oxygen Equivalent, CSCFH

97 L_LJ __ J__ _ ___,_ _ __:c-'-,--,---:-:-':-::-:--:::::::::--;:::::::;;----:;;:-,'.

O 5000 10000 15000 20000 25000 30000 35000 40000

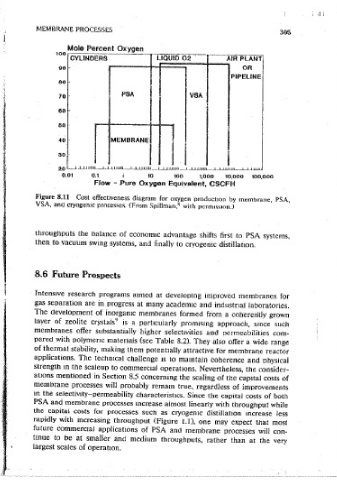

Figure 8.11 Cost effectiveness diagram for oxygen production by membrane, PSA,

CAPACITY (SCFH) VSA, and cryogenic prnccs!-cs. (From Spillman,'' with pcrm1ss1on.)

Figure 8.10 Cost_ effectiveness comparison for ~1trogen proctuct10n by membrane,

PSA, and crvogemc processes. (From Thorogood, with perm1ss1on.)

throughputs the balance of economic advantage shifts first to PSA systems,

then to vacuum swing systems, and finally to cryogenic distillation.

produce a high~purity product. The overall economic balance between the

PSA and membrane systems depends mamly on the scale of operation.

Membrane processes offer the best ch01ce at very small scales, PSA processes 8.6 Future Prospects

are most economic at reiatively large scales, and there is a sigilificant range of

intermediate scales in which there ts very littie difference in costs between Intensive research programs aimed at developing irr1-Proved membranes for

these processes. Although the breakeven pomts between these different gas separation are in orogress at many academic and industnat laboratories.

regions are continually changing as the technology evolves, this oualitative The development of inorganic membranes fonned from a coheren'tly grown

pattern 1s unlikely to change substantially. layer of zeolite crystais 9 is a part1cuiarly promising approach, srnce such

membranes offer substantially higher selectivities and permeabilities com-

pared with polymenc materials (see Table 8.2). They also offer a wide range

of thermal stability, making them potentially attractive for membrane reactor

8.5.2 Oxygen Production

applications. The technical challenge 1s to mamtain Coherence and ohysicai

A similar economic comparison between the PSA and membrane oxygen strength m the scaleuo to commercial ooerat1ons. Nevertheless, the consider-

production processes is shown in Figure 8.11. The membrane orocess de- ations mentioned in Section 8.5 concerning the scaling of the capital costs of

pends on recovering the permeate product, and to recove.r the permeate m membrane processes will probably remam true, regardless of improvements

pure form would require two or three stages with mtermediate compressors m the s~Iectiv1ty-permeability characteristics. Since the capital costs of both

[Figure 8.9(c)l. Such a process is not econom1call)i competitive with the ~SA and membrane processes increase aimost linear!Y with throughput while

corresponding PSA oxygen process with a zeolite adsorbent m wh1c11 the the capital costs for processes such as cryogenic distillation mcrease iess

i O}..-ygen is recovered as the raffinate product. The membrane oxygen orocess rapidly with increasing throughout (Figure i. 1), one may expect that most

I 1 s therefore limited by economics to a single stage, anct this limits the product future commercial applications of PSA and membrane proc~sses will con-

I ounty to about 50% oxygen. Within this restncted range the PSA and tinue to be at smaller and medium throughputs, rather than at the very

largest scales of operation.

membrane processes are competitive, but at higher purities and higher

-L