Page 19 - Principles and Applications of NanoMEMS Physics

P. 19

1. NANOELECTROMECHANICAL SYSTEMS 5

solvent-free dry layer. The resulting PR film thickness is inversely

proportional to the square root of the rotational speed, and directly

proportional to the percent of solids in it. Determining these parameters is

one of the first steps in developing a process.

1.2.1.2 Wafer Patterning

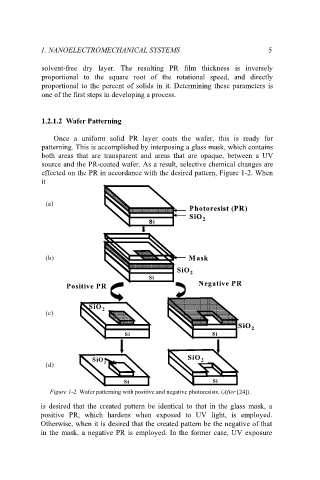

Once a uniform solid PR layer coats the wafer, this is ready for

patterning. This is accomplished by interposing a glass mask, which contains

both areas that are transparent and areas that are opaque, between a UV

source and the PR-coated wafer. As a result, selective chemical changes are

effected on the PR in accordance with the desired pattern, Figure 1-2. When

it

(a)

(a)

Photoresist (PR

Photoresist (PR) )

SiO 2 2

SiO

Si

Si

Mask

(b) Mask

(b)

SiO 2 2

SiO

Si Si

Negative PR

Negative PR

Positive PR

Positive PR

SiO

SiO 2 2

(c)

(c)

SiO

SiO

2 2

Si Si Si Si

SiO

SiO

SiO SiO 2 2

(d)

(d) 2 2

Si Si Si Si

Figure 1-2. Wafer patterning with positive and negative photoresists. (After [24]).

is desired that the created pattern be identical to that in the glass mask, a

positive PR, which hardens when exposed to UV light, is employed.

Otherwise, when it is desired that the created pattern be the negative of that

in the mask, a negative PR is employed. In the former case, UV exposure