Page 23 - Principles and Applications of NanoMEMS Physics

P. 23

1. NANOELECTROMECHANICAL SYSTEMS 9

the developer from permeating the PR film, no film swelling is produced and

a greater resolution is possible [23].

Electron beam lithography also utilizes negative and positive resists. In a

negative resist, the electron beam prompts cross-linking of the polymer,

which results on increased molecular weight, increased resistance to the

developer, and swelling during development. A common negative resist used

with electron beam lithography is COP, poly (glycidylmethacrylate-co-ethyl

1

m

acrylate), which renders a resolution of µ . In a positive resist, the

electron beam causes chemical bond breaking, reduced molecular weight,

and reduced resistance to dissolution during development. Common positive

resists used with electron beam lithography include poly(methyl

methacrylate) (PMMA) and poly(butane-1 ketone) (PBS), which render a

resolution of 1.0 µ m.

X-ray lithography also utilizes negative and positive resists, in particular,

COP, PBS and PMMA with resolution similar to that stated above is

obtained.

1.2.1.3 Etching

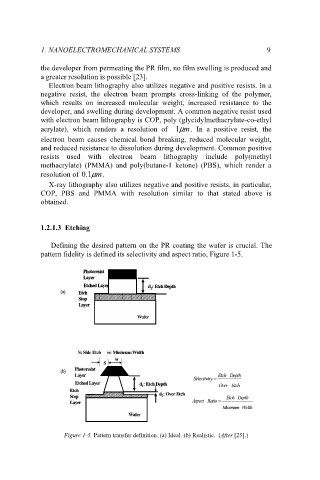

Defining the desired pattern on the PR coating the wafer is crucial. The

pattern fidelity is defined its selectivity and aspect ratio, Figure 1-5.

Photoresist

Photoresist

Layer

Layer

Etched Layer d 1 : Etch Depth

Etched Layer

d 1 : Etch Depth

(a) Etch

(a)

Etch

Stop

Stop

Layer

Layer

Wafer

Wafer

S: Side Etch w: Minimum Width

w: Minimum Width

S: Side Etch

w w

S S

Photoresist

Photoresist

(b)

(b)

Layer Etch DepthEtch Depth

Layer

S

Selectivityelectivit y = =

Etched Layer

Etched Layer d 1 : Etch Depth Over EtchOver Etch

d 1 : Etch Depth

Etch

Etch

d 2 : Over Etch

d 2 : Over Etch

Stop Et Depth

Stop

Etch Depthch

As

Layer

Layer Aspect Ratiopect Ratio = =

Mi

Minimum Widthnimum Width

Wafer

Wafer

Figure 1-5. Pattern transfer definition. (a) Ideal. (b) Realistic. (After [25].)