Page 25 - Principles and Applications of NanoMEMS Physics

P. 25

1. NANOELECTROMECHANICAL SYSTEMS 11

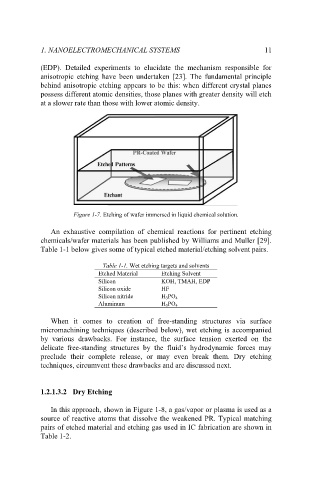

(EDP). Detailed experiments to elucidate the mechanism responsible for

anisotropic etching have been undertaken [23]. The fundamental principle

behind anisotropic etching appears to be this: when different crystal planes

possess different atomic densities, those planes with greater density will etch

at a slower rate than those with lower atomic density.

Figure 1-7. Etching of wafer immersed in liquid chemical solution.

An exhaustive compilation of chemical reactions for pertinent etching

chemicals/wafer materials has been published by Williams and Muller [29].

Table 1-1 below gives some of typical etched material/etching solvent pairs.

Table 1-1. Wet etching targets and solvents

Etched Material Etching Solvent

Silicon KOH, TMAH, EDP

Silicon oxide HF

Silicon nitride H 3 PO 4

Aluminum H 3 PO 4

When it comes to creation of free-standing structures via surface

micromachining techniques (described below), wet etching is accompanied

by various drawbacks. For instance, the surface tension exerted on the

delicate free-standing structures by the fluid’s hydrodynamic forces may

preclude their complete release, or may even break them. Dry etching

techniques, circumvent these drawbacks and are discussed next.

1.2.1.3.2 Dry Etching

In this approach, shown in Figure 1-8, a gas/vapor or plasma is used as a

source of reactive atoms that dissolve the weakened PR. Typical matching

pairs of etched material and etching gas used in IC fabrication are shown in

Table 1-2.