Page 29 - Principles and Applications of NanoMEMS Physics

P. 29

1. NANOELECTROMECHANICAL SYSTEMS 15

1.2.1.5 Sputtering

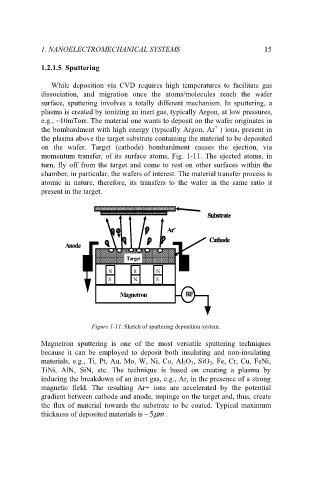

While deposition via CVD requires high temperatures to facilitate gas

dissociation, and migration once the atoms/molecules reach the wafer

surface, sputtering involves a totally different mechanism. In sputtering, a

plasma is created by ionizing an inert gas, typically Argon, at low pressures,

e.g., ~10mTorr. The material one wants to deposit on the wafer originates in

+

the bombardment with high energy (typically Argon, Ar ) ions, present in

the plasma above the target substrate containing the material to be deposited

on the wafer. Target (cathode) bombardment causes the ejection, via

momentum transfer, of its surface atoms, Fig. 1-11. The ejected atoms, in

turn, fly off from the target and come to rest on other surfaces within the

chamber, in particular, the wafers of interest. The material transfer process is

atomic in nature, therefore, its transfers to the wafer in the same ratio it

present in the target.

Substrate

Substrate

Ar

Ar + +

Cathode

Cathode

Anode

Anode

Target

Target

N N N N S S S S N N N N

S S S S N N N N S S S S

RF

Magnetron

Magnetron RF

Figure 1-11. Sketch of sputtering deposition system.

Magnetron sputtering is one of the most versatile sputtering techniques

because it can be employed to deposit both insulating and non-insulating

materials, e.g., Ti, Pt, Au, Mo, W, Ni, Co, Al 2O 3, SiO 2, Fe, Cr, Cu, FeNi,

TiNi, AlN, SiN, etc. The technique is based on creating a plasma by

inducing the breakdown of an inert gas, e.g., Ar, in the presence of a strong

magnetic field. The resulting Ar+ ions are accelerated by the potential

gradient between cathode and anode, impinge on the target and, thus, create

the flux of material towards the substrate to be coated. Typical maximum

m

thickness of deposited materials is ~ µ .

5