Page 28 - Principles and Applications of NanoMEMS Physics

P. 28

14 Chapter 1

Table 1-3. Common CVD reactions and deposition temperatures for

pertinent materials. [24]

Product Reactants Deposition temperature (°C)

Silicon dioxide SiH 4 +CO 2 +H 2 850-950

SiCl 2 H 2 +N 2 O 850-900

SiH 4 +N 2 O 750-850

SiH 4 +NO 650-750

Si(OC 2 H5) 4 650-750

400-450

SiH 4 +O 2

Silicon nitride SiH 4 +NH 3 700-900

650-750

SiCl 2 H 2 +NH 3

Polysilicon SiH 4 600-650

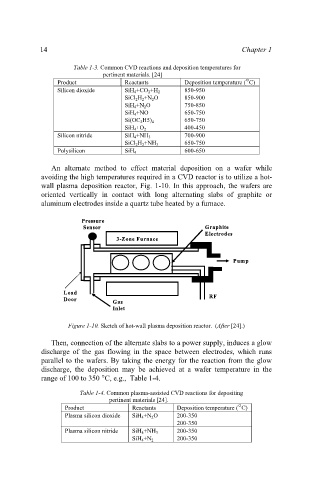

An alternate method to effect material deposition on a wafer while

avoiding the high temperatures required in a CVD reactor is to utilize a hot-

wall plasma deposition reactor, Fig. 1-10. In this approach, the wafers are

oriented vertically in contact with long alternating slabs of graphite or

aluminum electrodes inside a quartz tube heated by a furnace.

Pressure

Pressure

Graphite

Sensor Graphite

Sensor

Electrodes

Electrodes

3-Zone Furnace

3-Zone Furnace

Pump p

Pum

Load

Load

RF

RF

Door

Door

Gas

Gas

Inlet

Inlet

Figure 1-10. Sketch of hot-wall plasma deposition reactor. (After [24].)

Then, connection of the alternate slabs to a power supply, induces a glow

discharge of the gas flowing in the space between electrodes, which runs

parallel to the wafers. By taking the energy for the reaction from the glow

discharge, the deposition may be achieved at a wafer temperature in the

range of 100 to 350 °C, e.g., Table 1-4.

Table 1-4. Common plasma-assisted CVD reactions for depositing

pertinent materials [24].

Product Reactants Deposition temperature (°C)

Plasma silicon dioxide SiH 4 +N 2 O 200-350

200-350

Plasma silicon nitride SiH 4 +NH 3 200-350

200-350

SiH 4 +N 2