Page 26 - Principles and Applications of NanoMEMS Physics

P. 26

12 Chapter 1

Table 1-2. Etched material-etching gas pairs.

Silicon or Polysilicon SF 6 , CF 4

Silicon dioxide CHF 4 /H 2

Silicon nitride CF4/O2

Aluminum BCl 2

Two fluorine-containing gases have been recently adopted for dry

etching processes, namely, Xenon difluoride, XeF 2 [30] and Boron Fluoride,

BrF 3 [30]. XeF 2 enables an isotropic dry-etch process for silicon, which is

very selective to aluminum, silicon dioxide, silicon nitride and photoresist.

The XeF 2 gas is particularly useful in the post-processing of CMOS ICs. It

can be sublimated from its solid form at 1 Torr and room temperature and,

when applied to solid-phase Si, it obeys the following reaction:

2XeF 2 + SiÆ2Xe+SiF 4

XeF 2 etching of Si achieves high selectivity with a number of masking

materials, such as, SiO 2, Si 3N 4, Al, PR, and phosphosilicate glass (PSG), at

etching rates ranging from 1− 3µ m / min to as high as 40µ m / min [30],

and is characterized by the production of measurable amounts of heat. When

in the presence of water or vapor, XeF 2 reacts with them to form HF. In

terms of its potential application to nanostructure formation, XeF 2 etching

has the drawback that the resulting surfaces tend to have a granular finish

m

10

with a feature size of about µ .

Etch

Etch

Gas

Gas Pump

Pump

Wafers

Wafers

Ground Cathode

Ground

Cathode

Shield

Shield

RF

RF

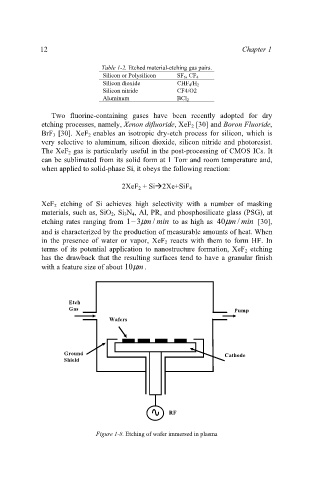

Figure 1-8. Etching of wafer immersed in plasma