Page 27 - Principles and Applications of NanoMEMS Physics

P. 27

1. NANOELECTROMECHANICAL SYSTEMS 13

BrF 3 on the other hand, enables isotropic etching of Si with masking

materials such as Al, Au, Cu, Ni, PR, SiO 2, and Si 3N 4, while achieving

surface finish feature size of 40-150nm. Dry etching, it may be concluded, is

not amenable to creating nanostructures.

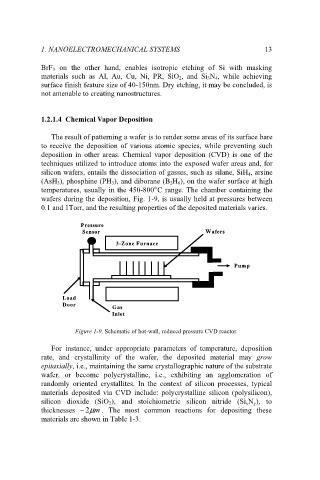

1.2.1.4 Chemical Vapor Deposition

The result of patterning a wafer is to render some areas of its surface bare

to receive the deposition of various atomic species, while preventing such

deposition in other areas. Chemical vapor deposition (CVD) is one of the

techniques utilized to introduce atoms into the exposed wafer areas and, for

silicon wafers, entails the dissociation of gasses, such as silane, SiH 4, arsine

(AsH 3), phosphine (PH 3), and diborane (B 2H 6), on the wafer surface at high

temperatures, usually in the 450-800°C range. The chamber containing the

wafers during the deposition, Fig. 1-9, is usually held at pressures between

0.1 and 1Torr, and the resulting properties of the deposited materials varies.

Pressure

Pressure

Sensor Wafers

Wafers

Sensor

3-Zone Furnace

3-Zone Furnace

Pum

Pump p

Load

Load

Door

Door

Gas

Gas

Inlet

Inlet

Figure 1-9. Schematic of hot-wall, reduced pressure CVD reactor.

For instance, under appropriate parameters of temperature, deposition

rate, and crystallinity of the wafer, the deposited material may grow

epitaxially, i.e., maintaining the same crystallographic nature of the substrate

wafer, or become polycrystalline, i.e., exhibiting an agglomeration of

randomly oriented crystallites. In the context of silicon processes, typical

materials deposited via CVD include: polycrystalline silicon (polysilicon),

silicon dioxide (SiO 2), and stoichiometric silicon nitride (Si xN y), to

m

2

thicknesses ~ µ . The most common reactions for depositing these

materials are shown in Table 1-3.