Page 32 - Principles and Applications of NanoMEMS Physics

P. 32

18 Chapter 1

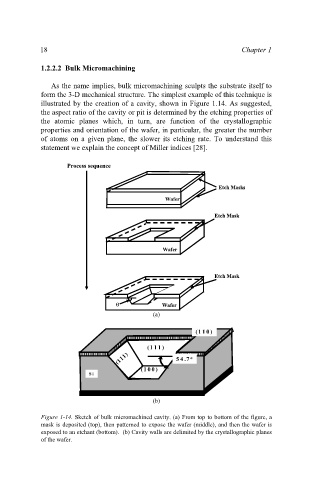

1.2.2.2 Bulk Micromachining

As the name implies, bulk micromachining sculpts the substrate itself to

form the 3-D mechanical structure. The simplest example of this technique is

illustrated by the creation of a cavity, shown in Figure 1.14. As suggested,

the aspect ratio of the cavity or pit is determined by the etching properties of

the atomic planes which, in turn, are function of the crystallographic

properties and orientation of the wafer, in particular, the greater the number

of atoms on a given plane, the slower its etching rate. To understand this

statement we explain the concept of Miller indices [28].

Process sequence

Process sequence

Etch Masks

Etch Masks

Wafer

Wafer

Etch Mask

Etch Mask

Wafer

Wafer

Etch Mask

Etch Mask

θ θ Wafer

Wafer

(a)

(110)

(110)

(111)

(111)

(111)

(111) 54.7 o o

54.7

(1 00)

(1 00)

Si

Si

(b)

Figure 1-14. Sketch of bulk micromachined cavity. (a) From top to bottom of the figure, a

mask is deposited (top), then patterned to expose the wafer (middle), and then the wafer is

exposed to an etchant (bottom). (b) Cavity walls are delimited by the crystallographic planes

of the wafer.