Page 30 - Principles and Applications of NanoMEMS Physics

P. 30

16 Chapter 1

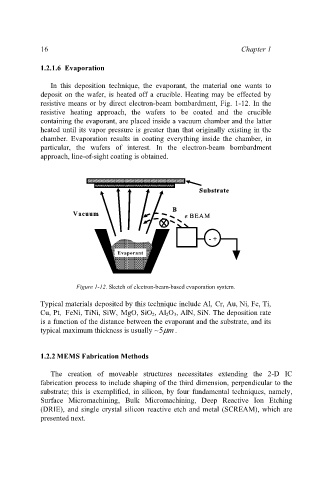

1.2.1.6 Evaporation

In this deposition technique, the evaporant, the material one wants to

deposit on the wafer, is heated off a crucible. Heating may be effected by

resistive means or by direct electron-beam bombardment, Fig. 1-12. In the

resistive heating approach, the wafers to be coated and the crucible

containing the evaporant, are placed inside a vacuum chamber and the latter

heated until its vapor pressure is greater than that originally existing in the

chamber. Evaporation results in coating everything inside the chamber, in

particular, the wafers of interest. In the electron-beam bombardment

approach, line-of-sight coating is obtained.

Substrate

Substrate

B B

Vacuum e BEAM

Vacuum

e BEAM

-+

-+

Evaporant

Evaporant

Figure 1-12. Sketch of electron-beam-based evaporation system.

Typical materials deposited by this technique include Al, Cr, Au, Ni, Fe, Ti,

Cu, Pt, FeNi, TiNi, SiW, MgO, SiO 2, Al 2O 3, AlN, SiN. The deposition rate

is a function of the distance between the evaporant and the substrate, and its

5

m

typical maximum thickness is usually ~ µ .

1.2.2 MEMS Fabrication Methods

The creation of moveable structures necessitates extending the 2-D IC

fabrication process to include shaping of the third dimension, perpendicular to the

substrate; this is exemplified, in silicon, by four fundamental techniques, namely,

Surface Micromachining, Bulk Micromachining, Deep Reactive Ion Etching

(DRIE), and single crystal silicon reactive etch and metal (SCREAM), which are

presented next.