Page 34 - Principles and Applications of NanoMEMS Physics

P. 34

20 Chapter 1

used for this purpose. However, to accommodate the possibility that the

plane might be parallel to one of the coordinate axes, in which case the

intersection would occur at infinity, the reciprocals of these points of

intersection, (1/h, 1/l, 1/k), are used instead. Figure 1-16(b) shows examples

crystallographic planes and their corresponding of Miller indices [28] for a

cubic crystal such as silicon.

The fact that the aspect ratio of bulk micromachined structures is limited

by the natural inclination of the crystallographic planes making up the walls,

motivated the development of techniques to increase it. The sections below

o

address two f these.

1.2.2.3 Deep Reactive Ion Etching

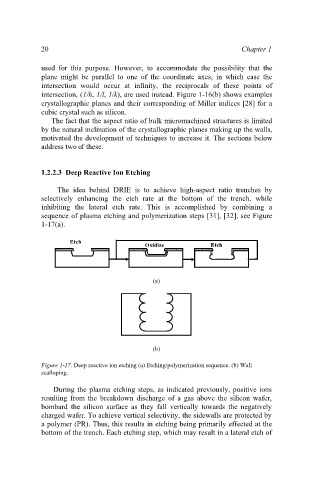

The idea behind DRIE is to achieve high-aspect ratio trenches by

selectively enhancing the etch rate at the bottom of the trench, while

inhibiting the lateral etch rate. This is accomplished by combining a

sequence of plasma etching and polymerization steps [31], [32], see Figure

1-17(a).

Etch

Etch

Oxidize Etch

Etch

Oxidize

(a)

(b)

Figure 1-17. Deep reactive ion etching (a) Etching/polymerization sequence. (b) Wall

scalloping.

During the plasma etching steps, as indicated previously, positive ions

resulting from the breakdown discharge of a gas above the silicon wafer,

bombard the silicon surface as they fall vertically towards the negatively

charged wafer. To achieve vertical selectivity, the sidewalls are protected by

a polymer (PR). Thus, this results in etching being primarily effected at the

bottom of the trench. Each etching step, which may result in a lateral etch of