Page 39 - Principles and Applications of NanoMEMS Physics

P. 39

1. NANOELECTROMECHANICAL SYSTEMS 25

D

I

R

P

I

L L IQ U ID P R E CUR S O R T O P D M S S

U

Q

E

P

O

M

D

S

CUR

R T

O

MASTER

(a)

M

PD M S STAMP

M

PHOTO RES IST

(b) (c)

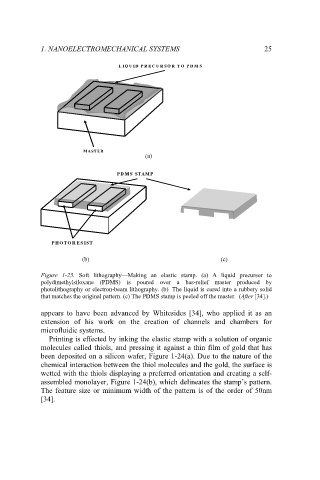

Figure 1-23. Soft lithography—Making an elastic stamp. (a) A liquid precursor to

polydimethylsiloxane (PDMS) is poured over a bas-relief master produced by

photolithography or electron-beam lithography. (b) The liquid is cured into a rubbery solid

that matches the original pattern. (c) The PDMS stamp is peeled off the master. (After [34].)

(

(

appears to have been advanced by Whitesides [34], who applied it as an

extension of his work on the creation of channels and chambers for

microfluidic systems.

Printing is effected by inking the elastic stamp with a solution of organic

molecules called thiols, and pressing it against a thin film of gold that has

been deposited on a silicon wafer, Figure 1-24(a). Due to the nature of the

chemical interaction between the thiol molecules and the gold, the surface is

wetted with the thiols displaying a preferred orientation and creating a self-

assembled monolayer, Figure 1-24(b), which delineates the stamp’s pattern.

The feature size or minimum width of the pattern is of the order of 50nm

[34].