Page 41 - Principles and Applications of NanoMEMS Physics

P. 41

1. NANOELECTROMECHANICAL SYSTEMS 27

the stamp’s recesses. Then, upon curing the polymer, this solidifies

according to the stamp’s pattern. The feature size for patterns thus created

may be as small as 10 nm [34].

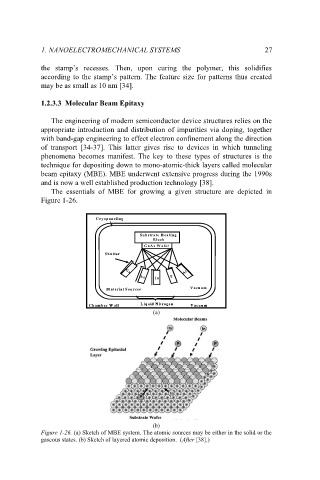

1.2.3.3 Molecular Beam Epitaxy

The engineering of modern semiconductor device structures relies on the

appropriate introduction and distribution of impurities via doping, together

with band-gap engineering to effect electron confinement along the direction

of transport [34-37]. This latter gives rise to devices in which tunneling

phenomena becomes manifest. The key to these types of structures is the

technique for depositing down to mono-atomic-thick layers called molecular

beam epitaxy (MBE). MBE underwent extensive progress during the 1990s

and is now a well established production technology [38].

The essentials of MBE for growing a given structure are depicted in

Figure 1-26.

C ryopanelin

C ryopaneling g

Substrate H eatin

Substrate H eating g

Bloc

Block k

GaAs W afe

GaAs W afer r

Shutte

Shutter r

Al Al

G

Ga a

A P P

A s s

In

In

V acuum

V acuum

M aterial Source

M aterial Sources s

L iquid N itrogen n

Vacuum m

Cham ber W a

Cham ber W all ll L iquid N itroge Vacuu

(a)

(b)

Figure 1-26. (a) Sketch of MBE system. The atomic sources may be either in the solid or the

gaseous states. (b) Sketch of layered atomic deposition. (After [38].)