Page 40 - Principles and Applications of NanoMEMS Physics

P. 40

26 Chapter 1

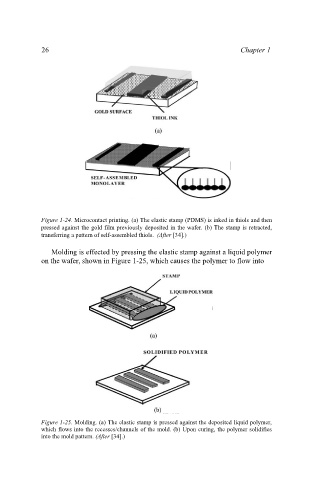

Figure 1-24. Microcontact printing. (a) The elastic stamp (PDMS) is inked in thiols and then

pressed against the gold film previously deposited in the wafer. (b) The stamp is retracted,

transferring a pattern of self-assembled thiols. (After [34].)

Molding is effected by pressing the elastic stamp against a liquid polymer

on the wafer, shown in Figure 1-25, which causes the polymer to flow into

Figure 1-25. Molding. (a) The elastic stamp is pressed against the deposited liquid polymer,

which flows into the recesses/channels of the mold. (b) Upon curing, the polymer solidifies

into the mold pattern. (After [34].)