Page 76 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 76

4.1 Introduction 73

Baffle

Most exchangers use baffles in tube bundle to make the shell-side fluid follow a narrower cross flow

path across the tubes. This increases the velocity and turbulence and results in higher shell-side heat

transfer coefficient. Baffles also ensure structural rigidity by supporting the tubes and prevent tube

vibration and sagging.

The clearance between baffle and shell (baffle clearance) should be low enough to minimise short

circuiting of fluid through such gap. However, if the clearance is too low the pull out of the tube bundle

for repair and maintenance becomes difficult. The centre to centre distance between baffles is called

baffle pitch or baffle spacing. Baffle spacing B, shell inside diameter D s, tube outside diameter D o and

pitch type and value P T governs the flow passage of the shell-side fluid thus influencing the level of

turbulence and shell-side heat transfer coefficient.

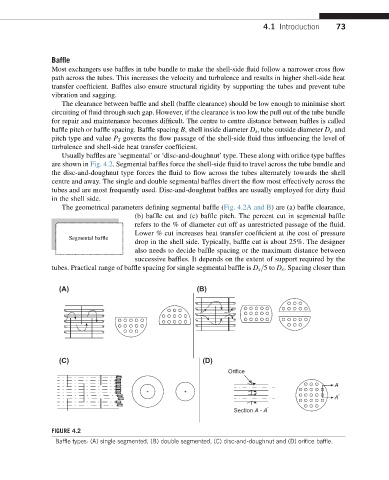

Usually baffles are ‘segmental’ or ‘disc-and-doughnut’ type. These along with orifice type baffles

are shown in Fig. 4.2. Segmental baffles force the shell-side fluid to travel across the tube bundle and

the disc-and-doughnut type forces the fluid to flow across the tubes alternately towards the shell

centre and away. The single and double segmental baffles divert the flow most effectively across the

tubes and are most frequently used. Disc-and-doughnut baffles are usually employed for dirty fluid

in the shell side.

The geometrical parameters defining segmental baffle (Fig. 4.2A and B) are (a) baffle clearance,

(b) baffle cut and (c) baffle pitch. The percent cut in segmental baffle

refers to the % of diameter cut off as unrestricted passage of the fluid.

Lower % cut increases heat transfer coefficient at the cost of pressure

Segmental baffle

drop in the shell side. Typically, baffle cut is about 25%. The designer

also needs to decide baffle spacing or the maximum distance between

successive baffles. It depends on the extent of support required by the

tubes. Practical range of baffle spacing for single segmental baffle is D s =5to D s . Spacing closer than

(A) (B)

(C) (D)

Orifice

A

A ′

Section A - A ′

FIGURE 4.2

Baffle types: (A) single segmented, (B) double segmented, (C) disc-and-doughnut and (D) orifice baffle.