Page 81 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 81

78 Chapter 4 Shell and tube heat exchanger

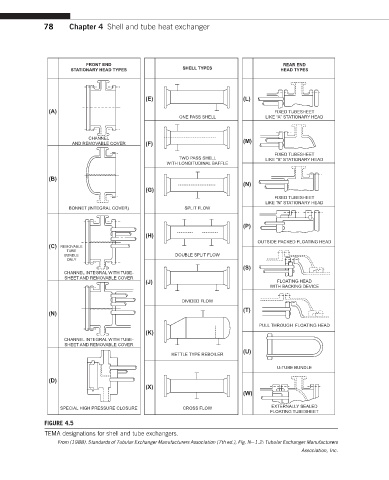

FRONT END REAR END

STATIONARY HEAD TYPES SHELL TYPES HEAD TYPES

(E) (L)

(A) FIXED TUBESHEET

ONE PASS SHELL LIKE “A” STATIONARY HEAD

CHANNEL (M)

AND REMOVABLE COVER (F)

FIXED TUBESHEET

TWO PASS SHELL LIKE “B” STATIONARY HEAD

WITH LONGITUDINAL BAFFLE

(B)

(N)

(G)

FIXED TUBESHEET

LIKE “N” STATIONARY HEAD

BONNET (INTEGRAL COVER) SPLIT FLOW

(P)

(H)

(C) REMOVABLE OUTSIDE PACKED FLOATING HEAD

TUBE

BUNDLE DOUBLE SPLIT FLOW

ONLY

(S)

CHANNEL INTEGRAL WITH TUBE-

SHEET AND REMOVABLE COVER

(J) FLOATING HEAD

WITH BACKING DEVICE

DIVIDED FLOW

(T)

(N)

PULL THROUGH FLOATING HEAD

(K)

CHANNEL INTEGRAL WITH TUBE-

SHEET AND REMOVABLE COVER

(U)

KETTLE TYPE REBOILER

U-TUBE BUNDLE

(D)

(X)

(W)

SPECIAL HIGH PRESSURE CLOSURE CROSS FLOW EXTERNALLY SEALED

FLOATING TUBESHEET

FIGURE 4.5

TEMA designations for shell and tube exchangers.

From (1988). Standards of Tubular Exchanger Manufacturers Association (7th ed.), Fig. Ne1.2: Tubular Exchanger Manufacturers

Association, Inc.