Page 87 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 87

84 Chapter 4 Shell and tube heat exchanger

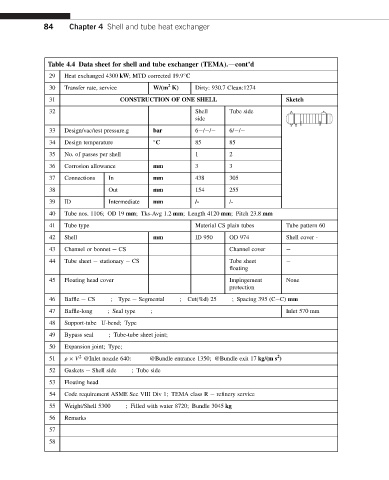

Table 4.4 Data sheet for shell and tube exchanger (TEMA).dcont’d

29 Heat exchanged 4300 kW; MTD corrected 19.9 C

2

30 Transfer rate, service W/(m K) Dirty: 930.7 Clean:1274

31 CONSTRUCTION OF ONE SHELL Sketch

32 Shell Tube side

side

33 Design/vac/test pressure.g bar 6 / / 6/ /

34 Design temperature C 85 85

35 No. of passes per shell 1 2

36 Corrosion allowance mm 3 3

37 Connections In mm 438 305

38 Out mm 154 255

39 ID Intermediate mm /- /-

40 Tube nos. 1106; OD 19 mm; Tks-Avg 1.2 mm; Length 4120 mm; Pitch 23.8 mm

41 Tube type Material CS plain tubes Tube pattern 60

42 Shell mm ID 950 OD 974 Shell cover -

43 Channel or bonnet e CS Channel cover e

44 Tube sheet e stationary e CS Tube sheet e

floating

45 Floating head cover Impingement None

protection

46 Baffle e CS ; Type e Segmental ; Cut(%d) 25 ; Spacing 395 (CeC) mm

47 Baffle-long ; Seal type ; Inlet 570 mm

48 Support-tube U-bend; Type

49 Bypass seal ; Tube-tube sheet joint;

50 Expansion joint; Type;

2

2

51 r V @Inlet nozzle 640: @Bundle entrance 1350; @Bundle exit 17 kg/(m s )

52 Gaskets e Shell side ; Tube side

53 Floating head

54 Code requirement ASME Sec VIII Div 1; TEMA class R e refinery service

55 Weight/Shell 5300 ; Filled with water 8720; Bundle 3045 kg

56 Remarks

57

58