Page 91 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 91

88 Chapter 4 Shell and tube heat exchanger

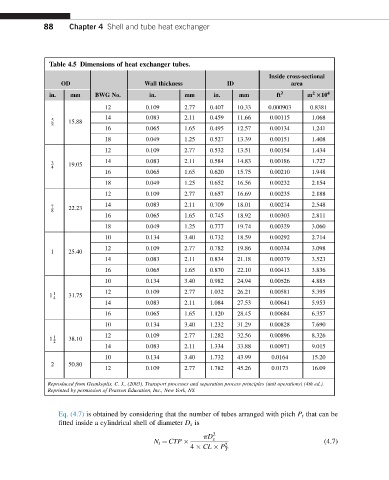

Table 4.5 Dimensions of heat exchanger tubes.

Inside cross-sectional

OD Wall thickness ID area

2

in. mm BWG No. in. mm in. mm ft 2 m 310 4

12 0.109 2.77 0.407 10.33 0.000903 0.8381

14 0.083 2.11 0.459 11.66 0.00115 1.068

5 15.88

8

16 0.065 1.65 0.495 12.57 0.00134 1.241

18 0.049 1.25 0.527 13.39 0.00151 1.408

12 0.109 2.77 0.532 13.51 0.00154 1.434

3 19.05 14 0.083 2.11 0.584 14.83 0.00186 1.727

4

16 0.065 1.65 0.620 15.75 0.00210 1.948

18 0.049 1.25 0.652 16.56 0.00232 2.154

12 0.109 2.77 0.657 16.69 0.00235 2.188

14 0.083 2.11 0.709 18.01 0.00274 2.548

7 22.23

8

16 0.065 1.65 0.745 18.92 0.00303 2.811

18 0.049 1.25 0.777 19.74 0.00329 3.060

10 0.134 3.40 0.732 18.59 0.00292 2.714

12 0.109 2.77 0.782 19.86 0.00334 3.098

1 25.40

14 0.083 2.11 0.834 21.18 0.00379 3.523

16 0.065 1.65 0.870 22.10 0.00413 3.836

10 0.134 3.40 0.982 24.94 0.00526 4.885

1 1 31.75 12 0.109 2.77 1.032 26.21 0.00581 5.395

4

14 0.083 2.11 1.084 27.53 0.00641 5.953

16 0.065 1.65 1.120 28.45 0.00684 6.357

10 0.134 3.40 1.232 31.29 0.00828 7.690

12 0.109 2.77 1.282 32.56 0.00896 8.326

1 1 38.10

2

14 0.083 2.11 1.334 33.88 0.00971 9.015

10 0.134 3.40 1.732 43.99 0.0164 15.20

2 50.80

12 0.109 2.77 1.782 45.26 0.0173 16.09

Reproduced from Geankoplis, C. J., (2003). Transport processes and separation process principles (unit operations) (4th ed.).

Reprinted by permission of Pearson Education, Inc., New York, NY.

Eq. (4.7) is obtained by considering that the number of tubes arranged with pitch P t that can be

fitted inside a cylindrical shell of diameter D s is

pD 2 s

N t ¼ CTP 2 (4.7)

4 CL P

T