Page 139 - Process Modelling and Simulation With Finite Element Methods

P. 139

126 Process Modelling and Simulation with Finite Element Methods

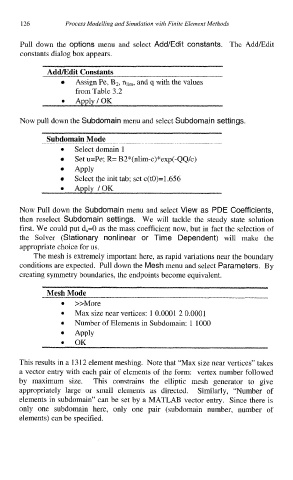

Pull down the options menu and select Add/Edit constants. The AddEdit

constants dialog box appears.

Add/Edit Constants

Assign Pe, Bz, nlim, and q with the values

from Table 3.2

Now pull down the Subdomain menu and select Subdomain settings.

Subdomain Mode

0 Select domain 1

Set u=Pe; R= B2*(nlim-c)*exp(-QQ/c)

Apply

Select the init tab; set c(t0)=1.656

Now Pull down the Subdomain menu and select View as PDE Coefficients,

then reselect Subdomain settings. We will tackle the steady state solution

first. We could put d,=O as the mass coefficient now, but in fact the selection of

the Solver (Stationary nonlinear or Time Dependent) will make the

appropriate choice for us.

The mesh is extremely important here, as rapid variations near the boundary

conditions are expected. Pull down the Mesh menu and select Parameters. By

creating symmetry boundaries, the endpoints become equivalent.

Mesh Mode

>>More

Max size near vertices: 1 0.0001 2 0.0001

0

0 Number of Elements in Subdomain: 1 1000

APPlY

0 OK

This results in a 1312 element meshing. Note that “Max size near vertices” takes

a vector entry with each pair of elements of the form: vertex number followed

by maximum size. This constrains the elliptic mesh generator to give

appropriately large or small elements as directed. Similarly, “Number of

elements in subdomain” can be set by a MATLAB vector entry. Since there is

only one subdomain here, only one pair (subdomain number, number of

elements) can be specified.