Page 33 - Process Modelling and Simulation With Finite Element Methods

P. 33

20 Process Modelling and Simulation with Finite Element Methods

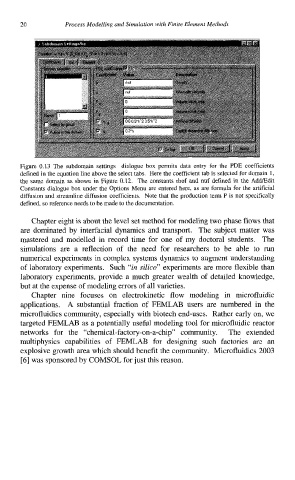

Figure 0.13 The subdomain settings dialogue box permits data entry for the PDE coefficients

defined in the equation line above the select tabs. Here the coefficient tab is selected for domain 1,

the same domain as shown in Figure 0.12. The constants rhof and nuf defined in the AddEdit

Constants dialogue box under the Options Menu are entered here, as are formula for the artificial

diffusion and streamline diffusion coefficients. Note that the production term P is not specifically

defined, so reference needs to be made to the documentation.

Chapter eight is about the level set method for modeling two phase flows that

are dominated by interfacial dynamics and transport. The subject matter was

mastered and modelled in record time for one of my doctoral students. The

simulations are a reflection of the need for researchers to be able to run

numerical experiments in complex systems dynamics to augment understanding

of laboratory experiments. Such “in silico” experiments are more flexible than

laboratory experiments, provide a much greater wealth of detailed knowledge,

but at the expense of modeling errors of all varieties.

Chapter nine focuses on electrokinetic flow modeling in microfluidic

applications. A substantial fraction of FEMLAB users are numbered in the

microfluidics community, especially with biotech end-uses. Rather early on, we

targeted FEMLAB as a potentially useful modeling tool for microfluidic reactor

networks for the “chemical-factory-on-a-chip” community. The extended

multiphysics capabilities of FEMLAB for designing such factories are an

explosive growth area which should benefit the community. Microfluidics 2003

[6] was sponsored by COMSOL for just this reason.