Page 162 - Process simulation and control using Aspen

P. 162

ASPEN PLUS SIMULATION OF EHSTILLATIQM MODELS 149

LIGHTS <

WATER

STMl

sir,-

STM2

BOT

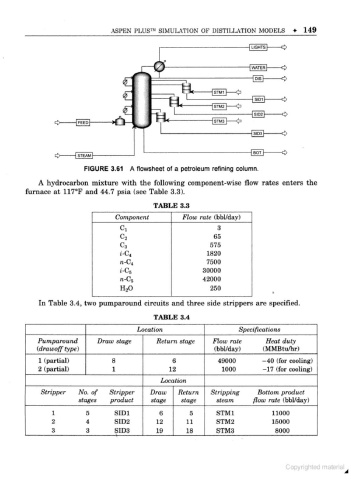

FIGURE 3.61 A flowsheet of a petroleum refining column.

A hydrocarbon mixture with the following component-wise flow rates enters the

furnace at 1170F and 44.7 psia (see Table 3.3).

TABLE 3.3

Component Flow rate (bbl/day)

Ci 3

c2 65

C3 575

i-C 1820

4

«-c 7500

4

i-C 30000

5

n-C 5 42000

H2O 250

In Table 3.4, two pumparound circuits and three side strippers are specified.

TABLE 3.4

Loeatum Specifications

Pumparound Draw stage Return stage Flow rate Heat duty

(drawoff type) (bbl/day) (MMBtu/hr)

1 (partial) 8 6 49000 - 40 (for cooling)

2 (partial) 1 12 1000 - 17 (for cooling)

Location

Stripper No. of Stripper Draw Return Stripping Bottom product

stages product stage stage steam flow rate (bbl/day)

1 5 SID1 6 5 STMl 11000

2 4 SID2 12 11 STM2 15000

3 3 SID3 19 18 STM3 8000

1