Page 330 - Reciprocating Compressors Operation Maintenance

P. 330

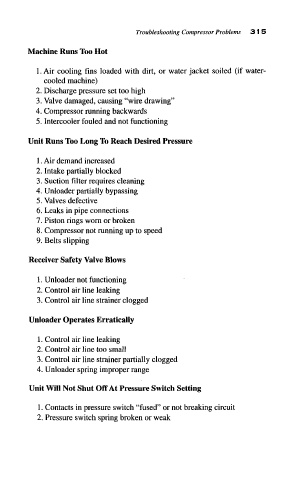

Troubleshooting Compressor Problems 315

Machine Runs Too Hot

1. Air cooling fins loaded with dirt, or water jacket soiled (if water-

cooled machine)

2. Discharge pressure set too high

3. Valve damaged, causing "wire drawing"

4. Compressor running backwards

5. Intercooler fouled and not functioning

Unit Runs Too Long To Reach Desired Pressure

1. Air demand increased

2. Intake partially blocked

3. Suction filter requires cleaning

4. Unloader partially bypassing

5. Valves defective

6. Leaks in pipe connections

7. Piston rings worn or broken

8. Compressor not running up to speed

9. Belts slipping

Receiver Safety Valve Blows

1. Unloader not functioning

2. Control air line leaking

3. Control air line strainer clogged

Unloader Operates Erratically

1. Control air line leaking

2. Control air line too small

3. Control air line strainer partially clogged

4. Unloader spring improper range

Unit Will Not Shut Off At Pressure Switch Setting

1. Contacts in pressure switch "fused" or not breaking circuit

2. Pressure switch spring broken or weak