Page 246 - Renewable Energy Devices and System with Simulations in MATLAB and ANSYS

P. 246

Electric Generators and their Control for Large Wind Turbines 233

×10 4 Component weight

3

Iron used

Stator iron

2.5

Copper

PM

2 Rotor iron

Machine

Weight (kg) 1.5

1

0.5

0

0 200 400 600 800 1000 1200

(a) Steps

×10 5 Cost

2

1.8

1.6

1.4 Copper

Material cost (USD) 0.8 1 Lamination

1.2

PM

Rotor iron

0.6 Weight

0.4

0.2

0

0 200 400 600 800 1000 1200

(b) Steps

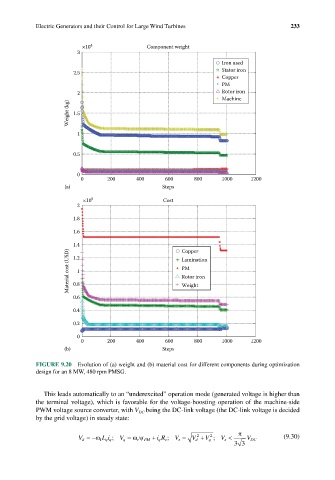

FIGURE 9.20 Evolution of (a) weight and (b) material cost for different components during optimization

design for an 8 MW, 480 rpm PMSG.

This leads automatically to an “underexcited” operation mode (generated voltage is higher than

the terminal voltage), which is favorable for the voltage-boosting operation of the machine-side

PWM voltage source converter, with V being the DC-link voltage (the DC-link voltage is decided

DC

by the grid voltage) in steady state:

π

2

2

Li q ; V q = ω ψ PM + i R s ; V s = V d + V q ; V s < (9.30)

V d =−ω 1 q r q V DC

33